In the construction and industry sectors, the use of seamless pipes is gaining significant attention. Experts like John Smith, a renowned engineer, once stated, "Seamless pipes offer unmatched durability and efficiency for modern projects." This perspective highlights the growing reliance on seamless pipes for various applications.

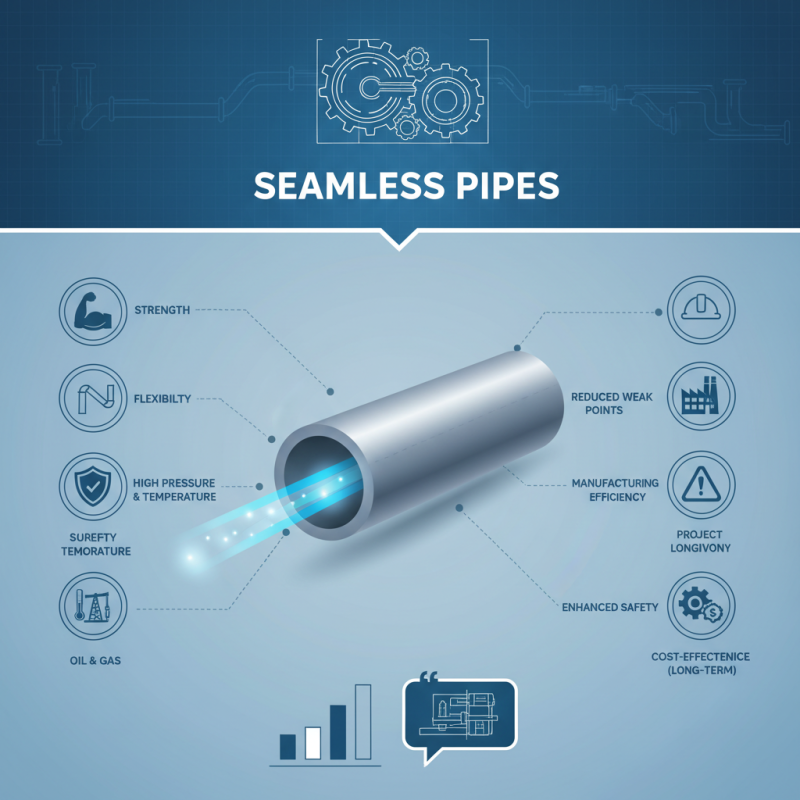

Seamless pipes excel in providing strength and flexibility. Their design minimizes weak points, reducing the risk of failure. Projects requiring high pressure and temperature often utilize these pipes. Additionally, seamless pipes are crucial in industries like oil and gas, where safety is paramount.

However, there are challenges. The manufacturing process is more complex than welded pipes. This complexity can lead to higher costs. It's vital to weigh the pros and cons carefully, as seamless pipes may not be suitable for every project. Nonetheless, their advantages make them a primary choice for many engineers.

Seamless pipes are increasingly valued in construction and industry due to their enhanced structural integrity and safety. These pipes are produced without welding joints, reducing weak points. According to a study by the American Society of Mechanical Engineers, seamless pipes exhibit higher pressure resistance. This makes them ideal for high-stress environments like oil and gas industries.

Furthermore, seamless pipes can withstand extreme temperatures. A research paper from the Journal of Materials Engineering highlights their performance in both high and low-temperature scenarios. This versatility means they can be used in various applications, from structural components to fluid transportation. While the production process is often more complex, the benefits often outweigh the costs.

Safety is paramount in construction. Seamless pipes minimize the risk of leaks. Reports indicate that failures in welded joints lead to about 30% of pipeline incidents. By using seamless options, companies can enhance safety protocols. However, maintenance and inspection remain critical. Regular checks are necessary to ensure long-term performance. The choice of seamless pipes should be balanced with ongoing quality control measures.

Seamless pipes are gaining popularity in construction and industry due to their robust nature. One of the key advantages is the reduced risk of leaks and failures. Statistics show that about 70% of piping failures are due to weld joints. Seamless pipes eliminate these weak points, leading to enhanced reliability.

The absence of seams makes these pipes less prone to corrosion and damage. This means fewer replacements over time. Companies can save significant costs on maintenance. In high-pressure environments, seamless pipes perform better. They withstand extreme conditions without compromising integrity.

However, the choice of seamless pipes isn't without challenges. Initial costs can be higher compared to welded alternatives. Some projects may benefit from the flexibility of welded pipes instead. Understanding the specific needs of a project is crucial. While seamless pipes offer many benefits, consideration of the application is necessary.

Seamless pipes have become a staple in construction and industry. Their cost-effectiveness in long-term applications is worth exploring. These pipes minimize the risk of leaks and failures, which can lead to costly repairs. Fewer joints mean fewer weak points, resulting in a more durable solution. Over time, this can save significant amounts on maintenance and operational costs.

In many projects, the initial investment in seamless pipes is higher. However, this upfront cost often pays off in the long run. Consider a manufacturing facility that relies on piping for fluid transport. If leaks occur, production halts. The financial impact can be devastating. Seamless pipes reduce this risk. They also typically have a longer lifespan. However, it's essential to perform regular inspections. Even robust materials can develop issues over time, but many find the effort worth the peace of mind.

Cost-effectiveness doesn't only mean lower prices. It also involves evaluating long-term reliability under various conditions. Some industries may overlook this vital aspect. They may choose cheaper options that ultimately fail sooner. It’s important to balance initial costs with potential future expenses. Thoughtful planning can lead to more sustainable investment choices in piping.

Seamless pipes showcase outstanding corrosion resistance, making them a preferred choice in construction and industry. These pipes, crafted without seams, minimize the risk of weaknesses. Their smooth surface can withstand harsh environments. They excel in power plants, oil and gas lines, and chemical processing facilities. Many industries benefit from this durability.

When selecting seamless pipes, consider your environment. Think about coastal areas and chemical exposure. The right pipe can save money over time. Maintenance costs can drop significantly if corrosion is minimal.

Remember, not all seamless pipes are created equal. Conduct thorough research before buying. Local conditions can impact performance. Consult industry experts for the best advice. Understanding your requirements is key to avoiding costly mistakes.

Seamless pipes play an essential role in various industrial applications. Their unique design minimizes the risk of leaks and material weaknesses. These pipes are widely used in power plants, chemical facilities, and oil refineries. In each case, seamless pipes offer reliability under extreme conditions.

The versatility of seamless pipes extends beyond traditional uses. They can be found in the automotive industry as well. These pipes serve as exhaust systems or fuel lines, ensuring efficient performance. However, the transition to seamless pipes may pose challenges. Some industries require significant adjustments in manufacturing processes.

Seamless pipes are also beneficial in construction projects. They provide structural support in high-rise buildings. Their strength allows for thinner walls, maximizing space. Despite their advantages, it’s crucial to consider material selection carefully. Using the wrong type may lead to complications in the long run.

| Benefit | Description | Applications |

|---|---|---|

| High Strength | Seamless pipes can withstand high pressure and stress. | Oil and gas drilling, water transport |

| Corrosion Resistance | These pipes have a higher resistance to corrosion compared to welded pipes. | Chemical processing, marine applications |

| Versatility | Suitable for various dimensions and material specifications. | Construction, HVAC systems |

| Weldability | Easily welded to other components in the assembly process. | Boilers, pressure vessels |

| Cost-Effectiveness | Long-lasting lifespan reduces replacement costs. | Water supply systems, industrial machinery |

| Lightweight | Easier to handle and transport compared to socket-welded pipes. | Construction, automotive industries |

| Improved Fluid Flow | Smooth interior surface reduces turbulence, increasing efficiency. | Pipelines, irrigation systems |

| Thermal Conductivity | Excellent thermal properties beneficial for heat exchange systems. | Heat exchangers, refrigeration |

| Resistance to High Temperatures | Ideal for applications involving extreme heat conditions. | Petrochemical industry, power generation |

| Aesthetic Appeal | Seamless pipes provide a cleaner look for visible applications. | Architectural features, decorative installations |