In the evolving landscape of plumbing, choosing the right materials is crucial. Copper pipes remain a top choice for both residential and commercial projects. According to a recent report by the National Plumbing Alliance, copper pipes account for approximately 20% of material choices in plumbing installations. This statistic reflects their ongoing popularity due to durability and efficiency.

Expert Robert Jenkins, a leading figure in plumbing innovation, emphasizes, "Copper pipes offer unmatched reliability and longevity." This statement underscores the importance of selecting high-quality materials for plumbing needs. Despite their benefits, some challenges persist. The market faces fluctuations in copper prices, impacting project budgets. Additionally, improper installation can lead to leaks and wasted resources.

These factors remind us that continuous evaluation of our choices is essential. As we look toward 2026, exploring the best copper pipes for plumbing will require not only understanding the materials but also an awareness of potential pitfalls in their application.

Choosing the right type of copper pipe for your plumbing needs can be daunting. There are various options available, each designed for specific uses. For instance, type K copper pipes have thick walls, making them durable and great for underground installations. However, they can be cumbersome to work with due to their weight.

On the other hand, type L pipes are thinner and easier to handle. They are commonly used in residential water systems. Still, their fragility comes into play when faced with extreme temperature changes. Type M is another option, known for being lightweight and cost-effective. Yet, they may not hold up under high pressure as well as other types.

When selecting a copper pipe, consider both the environment and the pressure of your plumbing system. Different projects may need different specifications. Think about long-term use, as some pipes may corrode over time. Research is essential, but so is practical experience. Some installation mistakes can lead to leaks or bursts. Reflect on your choices, and ensure they align with your project goals.

This chart displays the average diameters of different types of copper pipes commonly used in plumbing projects in 2026, aiding in the selection of the appropriate pipe for various plumbing needs.

When it comes to plumbing projects, choosing the right copper pipe is crucial. Two main types stand out: soft copper and rigid copper.

Soft copper is flexible and easy to work with. It can be bent without the need for fittings. This flexibility makes it ideal for tight spaces and intricate layouts. However, its softness also means it can be more prone to damage. Sharp objects or extreme temperatures can affect its integrity.

Rigid copper, on the other hand, is robust and good for straight runs. It's less likely to get damaged over time. This type can withstand higher pressures, making it preferable for some high-demand plumbing systems. However, installation requires more tools, including pipe cutters and fittings. The learning curve can be steep for beginners. Mistakes can lead to leaks or wasted materials.

Choosing between soft and rigid copper ultimately depends on the project. Consider the layout and pressure needs. Weigh the pros and cons of each type. Reflect on your skill level and resources. Avoid rushing the decision; take time to research. There’s no perfect answer, but understanding these differences can lead to better choices.

Choosing the right copper pipes for plumbing projects involves several key factors. First, consider the gauge of the pipe.

Thinner pipes can be less expensive but may not last as long under high pressure. Thicker pipes, while pricier, often provide greater durability and longevity.

Weighing these options is crucial for effective project management.

Another important aspect is the type of pipe you select. For instance, rigid pipes are great for specific applications, while flexible options allow for easier installation in tight spaces.

Each type serves different needs, and understanding these can prevent future issues. It's also essential to think about the environment where the pipes will be installed.

Humid areas may corrode pipes faster than dry spaces.

Additionally, take time to assess the installation process. Overlooking the need for proper insulation can lead to problems down the line. Mistakes can occur if measurements are inaccurate or if you don't account for expansion and contraction. Reflect on your choices carefully.

Each decision shapes the overall efficiency and effectiveness of your plumbing system.

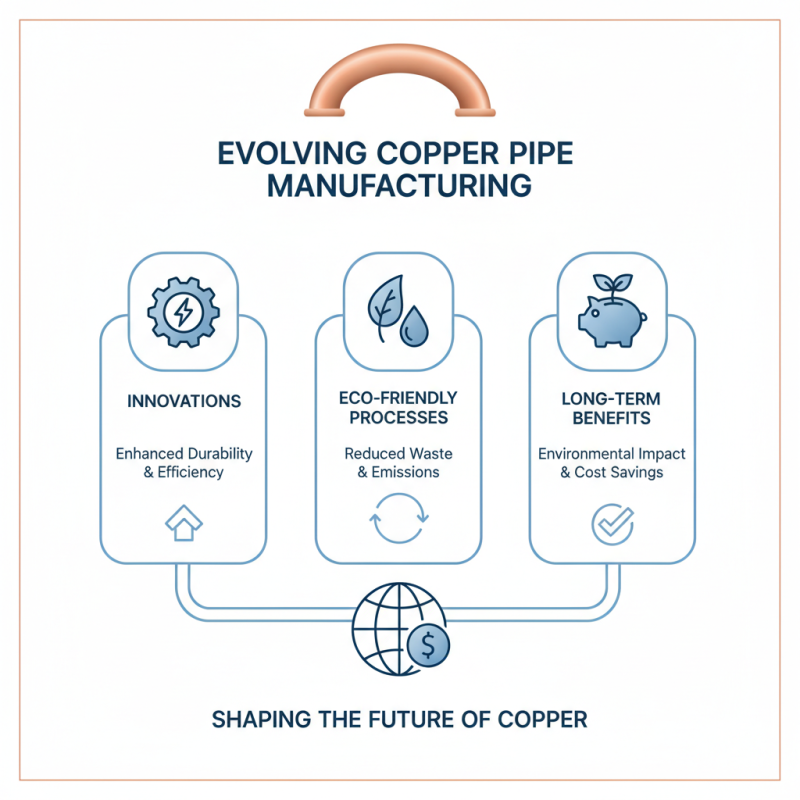

The copper pipe manufacturing industry is evolving rapidly. Innovations are shaping how pipes are made, enhancing their durability and efficiency. One significant trend is the development of eco-friendly production processes. Manufacturers are focusing on reducing waste and emissions. This shift benefits the environment and may lead to cost savings in the long run.

Another noteworthy trend is the increased use of advanced technologies in production. These technologies include automation and precision engineering. They help create more uniform and reliable copper pipes. However, there are challenges. Adopting these technologies requires investment and training. Not all manufacturers might keep pace with these innovations, causing uneven quality in the market.

Additionally, designs are becoming more versatile. Pipes are now made to fit a variety of applications, from traditional plumbing to modern heating systems. This adaptability is essential. Yet, not every new design proves to be effective in real-world scenarios. Industry players need to test these innovations thoroughly before widespread adoption. As we move into 2026, the focus will remain on balancing innovation with practicality.

When working with copper plumbing, preparation is key. Start by gathering all necessary tools before you begin. Make sure your workspace is clean and well-lit. Measure twice to avoid mistakes. Remember, cutting copper pipes can be tricky. A clean cut is crucial for a good fit.

Tips for soldering are essential. Heat the joint evenly, and don’t overdo it. Too much heat can damage the pipe. Use flux liberally to ensure a strong bond. After soldering, allow the joint to cool undisturbed. Rushing this step can create weak spots.

When installing copper pipes, think about the layout. Avoid sharp bends to reduce pressure loss. Use supports strategically to prevent sagging. Regular checks and maintenance can help identify issues early. Look for signs of corrosion that may indicate underlying problems. These practices can save time and money down the line.