As we approach 2026, the metal sheets market continues to evolve. Industry reports show a projected growth rate of 4.5% annually. This reflects an increasing demand for metal sheets across various sectors. Construction and manufacturing heavily rely on these materials for structural and functional applications.

Metal sheets are valued for their versatility and durability. They are used in everything from automotive components to home improvement projects. In 2025, the global demand for coated steel sheets reached approximately $90 billion. Such figures highlight the importance of choosing the right type of metal sheets for your specific projects.

Yet, the wide range of options can be overwhelming. Factors like thickness, finish, and alloy composition must be considered. Some choices may not meet the project requirements. A reflective approach is essential when selecting materials. Understanding these intricacies can lead to better results and more efficient use of resources in your upcoming endeavors.

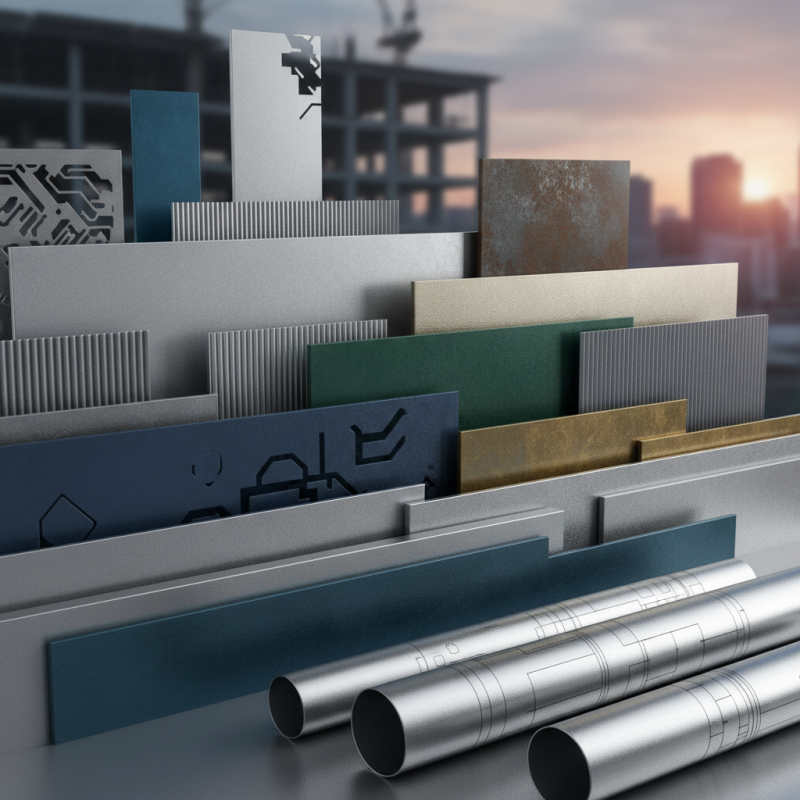

When selecting metal sheets for projects in 2026, it's essential to consider various types. Aluminum sheets remain popular due to their lightweight nature and excellent corrosion resistance. A recent industry report indicates that the demand for aluminum sheets is projected to grow by 5% annually. They are ideal for applications requiring a balance of strength and weight.

Steel sheets also hold a significant position. Their durability is unmatched, making them suitable for structural applications. According to market research, close to 60% of construction projects utilize steel sheets. However, galvanized options should be carefully evaluated. If not coated properly, they can rust over time.

Copper sheets, while less common, are gaining attention. Their electrical conductivity is superior, and aesthetic appeal is high for decorative tasks. Yet, they come with a higher price tag, which may deter some budget-conscious projects. Weighing the pros and cons is crucial. Each type of metal sheet presents unique benefits and challenges. Making informed choices ensures successful outcomes for your 2026 projects.

| Type of Metal Sheet | Thickness (mm) | Weight (kg/m²) | Common Uses | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum | 1.2 | 3.0 | Aerospace, automotive parts | Good |

| Stainless Steel | 1.5 | 5.0 | Kitchen appliances, medical devices | Excellent |

| Mild Steel | 2.0 | 7.8 | Construction, automotive | Fair |

| Galvanized Steel | 1.0 | 4.0 | Roofing, siding | Good |

| Copper | 0.8 | 8.9 | Electrical wiring, plumbing | Excellent |

When selecting metal sheets for your projects in 2026, several key features come into play. The thickness of the sheets is crucial. For structural projects, thickness often ranges from 1.5 mm to 4 mm. Thicker sheets offer more strength but can be harder to work with. In a recent industry report, 68% of professionals noted that thickness impacts durability and long-term performance.

Material composition is another factor to consider. Common choices include aluminum, stainless steel, and galvanized steel. Aluminum is lightweight and resistant to corrosion but may not provide the strength of steel. Conversely, stainless steel offers excellent strength but can be cost-prohibitive. A survey revealed that 72% of engineers prioritize material properties based on project requirements.

Surface finish is essential too. Smooth finishes are easier to clean but can be prone to scratches. Textured finishes hide imperfections better but may require more maintenance. A study showed that 54% of users found surface finish critical for aesthetic appeal and longevity. Always weigh these factors against the project's specific needs. Quality can vary, and neglecting these details can lead to issues down the line.

Metal sheets are essential in various industries. They serve diverse functions, from construction to automotive manufacturing. In 2026, the demand for high-quality metal sheets continues to rise. According to recent industry reports, the global metal sheet market is projected to grow significantly, driven by increasing applications.

In construction, metal sheets offer durability and corrosion resistance. Their lightweight nature makes them suitable for roofing and cladding. In the automotive industry, they are vital for body panels and frame structures. Research shows that around 35% of the metal sheet usage is in these applications alone.

Tip: Always choose the right thickness for your project. Thicker metal sheets may be more durable but also heavier and more challenging to work with.

In the aerospace sector, aluminum sheets are widely used. Their strength-to-weight ratio is unmatched. However, sourcing high-quality aluminum can be challenging. Some manufacturers may compromise on quality to reduce costs. So, it’s crucial to verify suppliers.

Tip: Conduct thorough research before selecting materials. This approach helps ensure safety and longevity in your projects.

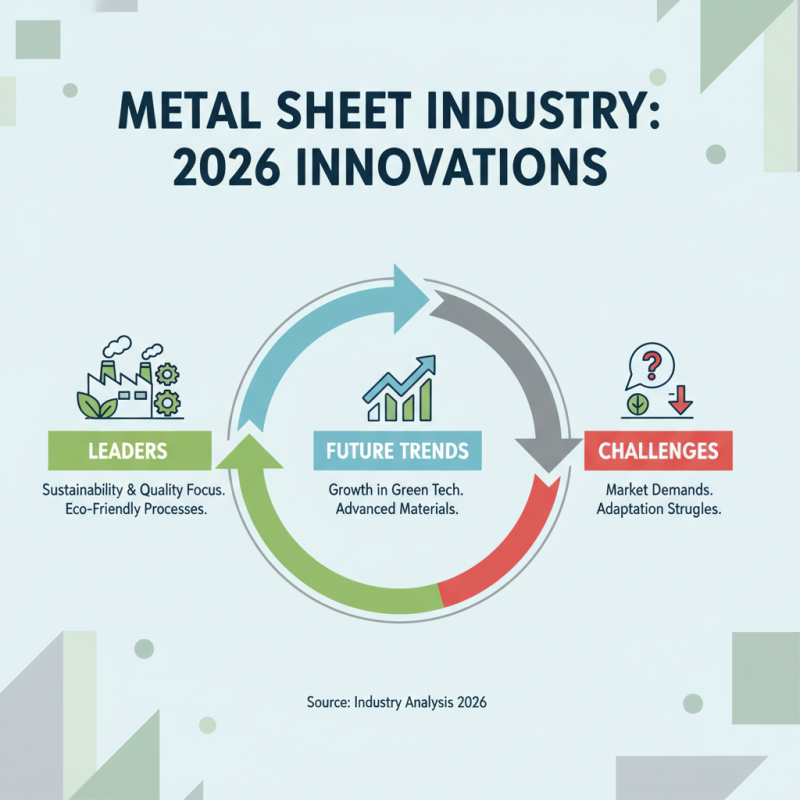

In 2026, the metal sheet industry is expected to see significant innovations. Several manufacturers are emerging as leaders. They focus on sustainability and quality. It’s impressive to see how these companies adopt eco-friendly processes. However, not all manufacturers will succeed. Some may struggle to keep up with market demands.

These producers offer various metal types. Stainless steel is popular for its durability. Aluminum sheets are lightweight and versatile. Copper is often chosen for its conductivity. Each material serves a unique purpose. It is crucial to choose the right type for your project. Yet, many might overlook this and regret it later.

As you explore options, consider the manufacturing processes. Quality control is vital. Some companies may cut corners, leading to less reliable products. Research is essential to find trustworthy sources. Conversations with industry professionals can provide insight. Ultimately, the best choice will depend on your specific needs and project goals.

Sustainability trends in metal sheet production are evolving rapidly. In 2023, a report showed that over 30% of steel was produced using recycled materials. This is a significant increase from just 15% a decade ago. The industry is actively working to reduce its carbon footprint. Innovative techniques are emerging to improve recycling processes.

Using sustainable energy sources during production is also gaining traction. Reports indicate that approximately 40% of metal sheet manufacturers are now relying on renewable energy. Solar and wind power are key players in this shift. However, challenges remain. Not every facility can switch to green energy easily. The capital investment required is substantial, and not all companies are equipped for this change.

Furthermore, consumers are demanding more eco-friendly products. A 2022 survey found that 72% of buyers prefer materials made with sustainability in mind. This figure is expected to rise. However, some manufacturers struggle to meet these expectations. They face hurdles in sourcing materials and technology for sustainable production. The path to sustainability is complex but essential for future projects.