When embarking on a construction or manufacturing project, selecting the appropriate materials is crucial for ensuring optimal performance and structural integrity. Among the variety of materials available, round pipes play a significant role in applications ranging from plumbing and HVAC systems to structural frameworks and industrial manufacturing. According to a recent market analysis by the Global Steel Pipes and Tubes Industry, the demand for round pipes is projected to grow at a compound annual growth rate (CAGR) of 3.5% through 2026. This growth is driven by an increasing investment in infrastructure projects and the rising need for efficient liquid and gas transportation.

In 2023, choosing the best round pipe sizes is essential for engineers and project managers aiming to adhere to industry standards while optimizing costs. The appropriate size not only enhances the aesthetic appeal but also directly affects the flow capacity, pressure ratings, and overall durability of the piping system. Industry guidelines, such as those from the American Society for Testing and Materials (ASTM), provide invaluable insights into selecting the right dimensions and specifications based on application-specific requirements. As we delve into the recommended sizes and their applications, understanding the interplay of diameter, wall thickness, and material properties will be crucial for achieving success in your next project.

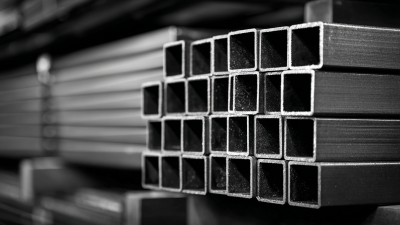

Understanding standard round pipe sizes is essential for professionals in construction, plumbing, and other industries that rely on piping systems. As of 2023, the most commonly used standard sizes in the United States are classified by nominal diameters, typically ranging from ½ inch to 12 inches for plumbing applications, with larger sizes available for industrial uses. According to the American Society for Testing and Materials (ASTM), the average internal diameter of a standard 1-inch pipe is approximately 1.049 inches, which provides a clear understanding of how nominal sizes can differ from actual measurements.

Furthermore, it is crucial to consider the wall thickness of pipes, which directly affects their durability and application suitability. For instance, schedule 40 pipes, which are widely utilized in various projects, have a wall thickness that varies depending on the pipe's diameter. The National Institute of Standards and Technology (NIST) reports that using the correct schedule pipe is necessary to prevent system failures and ensure compliance with safety standards. In 2023, there is a growing need for robust pipes that can withstand higher pressures and corrosive environments, leading to an increased preference for larger diameter pipes in industrial sectors. This shift emphasizes the importance of understanding not just the sizes, but also the materials and configurations best suited for specific applications.

When selecting the best round pipe sizes for your next project, several factors must be considered to ensure optimal performance and efficiency. Firstly, the intended application plays a significant role. Whether the pipes will be used for plumbing, structural support, or fluid transportation can influence the required diameter, wall thickness, and material. Projects demanding high pressure will necessitate thicker walls, while those involving gravity-fed systems might require larger diameters to accommodate flow rates.

Another crucial aspect to consider is the environmental conditions the pipes will face. Factors such as temperature fluctuations, exposure to corrosive substances, and potential physical stresses can dictate the choice of material and pipe size. For example, pipes exposed to extreme temperatures might require insulation or specific materials that can withstand thermal expansion. Furthermore, it's essential to adhere to local regulations and industry standards, which may stipulate minimum pipe sizes for safety and efficiency in specific applications. The combination of these considerations will lead to a well-informed decision, ensuring the longevity and reliability of the pipe system in your project.

This chart illustrates the most commonly used round pipe sizes in construction projects in 2023, along with their associated flow rates. Selecting the right size is crucial for ensuring optimal performance in plumbing and fluid transport applications.

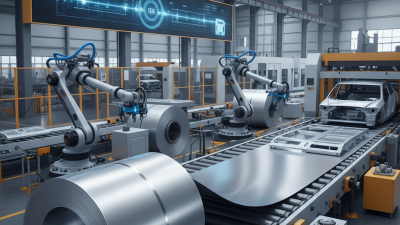

Round pipes are essential components in a multitude of industries, serving various crucial functions. In the construction sector, they are predominantly used for structural supports and utility conduits. These pipes provide the necessary strength and durability to withstand environmental pressures while efficiently routing electrical wires and plumbing systems. The versatility in pipe sizes allows architects and engineers to tailor their designs to specific project requirements, ensuring safety and functionality.

In the manufacturing and automotive industries, round pipes are critical for fluid transport systems. Whether for carrying liquids like oil and gas or gases in HVAC systems, the round shape facilitates a smooth flow, minimizing turbulence and optimizing performance. Additionally, in the agricultural sector, these pipes are used in irrigation systems, aiding in the effective distribution of water to crops. Their resilience against corrosion makes them ideal for outdoor applications, where exposure to various elements is a constant factor. Thus, the selection of the right pipe size can greatly enhance efficiency and sustainability across different industrial applications.

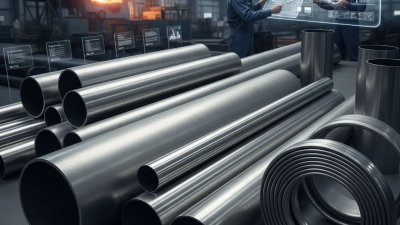

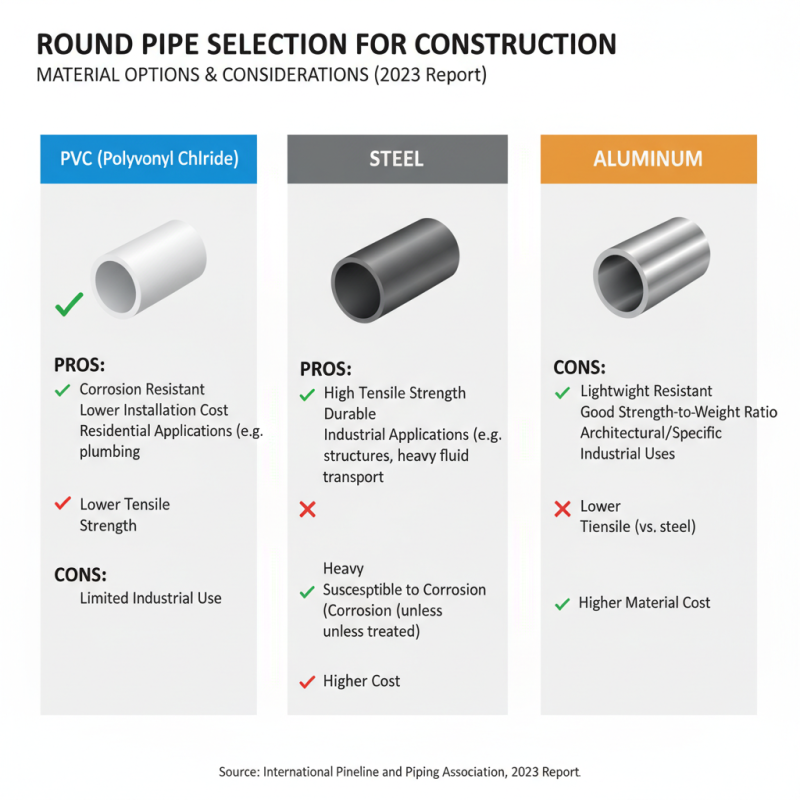

When selecting round pipes for construction projects, it's crucial to weigh the material options available and their inherent pros and cons. Common materials include PVC, steel, and aluminum, each presenting distinct benefits and drawbacks. According to a 2023 report from the International Pipeline and Piping Association, PVC pipes are favored in residential applications due to their lightweight nature and resistance to corrosion. They typically have a lower installation cost, making them ideal for budget-conscious projects. However, PVC has lower tensile strength compared to metals, which can limit its use in more demanding industrial applications.

On the other hand, steel pipes are celebrated for their durability and high strength, making them suitable for high-pressure systems or applications requiring structural integrity. A study published by the Global Steel Institute highlights that steel pipes have a longer lifespan than their plastic counterparts, often exceeding 50 years with proper maintenance. However, they can be prone to rust if not adequately protected, which can increase long-term maintenance costs. Aluminum pipes offer a lightweight alternative with good corrosion resistance, and their strength-to-weight ratio makes them an attractive choice for specialized applications. Yet, they may come with a higher initial cost compared to PVC and require careful handling due to their susceptibility to dents and dings.

When deciding on the best round pipe size and material for a project, it's essential to consider the specific requirements and trade-offs inherent in each material option. Understanding these factors can optimize performance and cost-effectiveness for the intended application.

When it comes to measuring round pipes for your next project, precision is paramount. Start by determining the pipe's intended application, as this will directly influence the dimensions you choose. To ensure accurate measurements, equip yourself with a caliper or tape measure, making sure to measure the diameter at multiple points along the pipe’s length to account for any irregularities. Don’t forget to consider the wall thickness, which can affect the overall diameter and must be factored into your calculations, especially if you're working in tight spaces or need to connect fittings.

When it comes to installation, preparation is key. Before securing the pipes in place, double-check your layout to avoid costly mistakes. Use appropriate supports and brackets to maintain the integrity of the piping system, ensuring that load is evenly distributed. If your project involves joining multiple pipe sections, ensure that your connectors are suitable for the pipe size and type to prevent leaks. It's also advisable to follow industry standards regarding installation angles and support spacing to maintain system efficiency and longevity.