Structural steel plays a pivotal role in modern construction, offering unparalleled strength and durability for a wide array of architectural designs. As the backbone of buildings, bridges, and other infrastructures, its application is critical in ensuring that structures can withstand various environmental challenges while maintaining safety and stability. Understanding the best practices for utilizing structural steel is essential for architects, engineers, and construction professionals aiming to enhance the resilience and longevity of their projects.

In this discussion, we will explore ten essential tips that focus on optimizing the use of structural steel in construction. These tips are designed not only to improve the strength of structures but also to enhance their durability over time. From proper material selection to innovative design strategies, these insights will provide a comprehensive framework for achieving superior performance in building projects. By adhering to these guidelines, construction professionals can ensure that their work stands the test of time, reflects high standards of quality, and meets the demands of today's dynamic construction environment.

Selecting the right grade of structural steel is critical for ensuring the strength and durability of construction projects. Structural steel is categorized into various grades based on its chemical composition and mechanical properties, which directly affect its performance in construction applications. According to the American Institute of Steel Construction (AISC), selecting the appropriate grade can lead to a 20-30% improvement in overall material efficiency, significantly impacting project budget and sustainability.

When choosing a grade, factors such as yield strength, tensile strength, and ductility must be taken into account. For instance, S235 and S355 are common grades used in construction; S355 offers higher yield strength, making it suitable for heavier loads and more demanding structural applications.

The World Steel Association reports that using higher-grade steel can reduce the amount of material required, thereby decreasing both cost and environmental impact. Additionally, understanding the material's behavior under various conditions, including temperature fluctuations and potential corrosive environments, is essential for long-term durability. This informed selection process not only enhances the structural integrity but also ensures compliance with industry standards and regulations, leading to safer and more reliable construction outcomes.

Corrosion is one of the most significant threats to the durability of structural steel in construction. The presence of moisture, oxygen, and various environmental factors can lead to the gradual deterioration of steel structures. Understanding this impact is critical for ensuring the long-term strength and integrity of any construction project. To mitigate corrosion issues, it's essential to implement preventive measures from the start.

One effective strategy is to utilize protective coatings that create a barrier between the steel and corrosive elements. Applying these coatings not only extends the life of the steel but also maintains its aesthetic appeal. Regular inspections are equally important; modern technology allows for non-destructive testing methods that can identify corrosion before it becomes a serious problem.

Additionally, selecting steel grades that are inherently more resistant to corrosion can enhance durability. Some alloys are specifically designed to withstand harsh environments, reducing maintenance needs and extending the lifespan of structures. Incorporating proper drainage systems and ventilation in designs further helps minimize moisture accumulation, which is a primary catalyst for corrosion.

By integrating these tips into construction practices, professionals can significantly enhance the strength and longevity of steel structures.

When designing for load-bearing capacity in structural steel, it's crucial to consider various factors that affect strength and durability. Structural steel is known for its high strength-to-weight ratio, making it a favored choice in construction. According to the American Institute of Steel Construction (AISC), proper design can increase the load-bearing capacity by up to 30% when utilizing advanced optimization techniques. Precise calculations and simulations should be employed to ensure that all elements work cohesively under maximum expected loads, including dead loads, live loads, and environmental factors.

One critical tip is to optimize connection design. Connections often serve as the weak points in structural steel assemblies. The AISC recommends using welded connections for high-strength applications, which can significantly improve overall stability. Additionally, ensuring that all connections are adequately sized and detailed can prevent unexpected failures and enhance load transfer across the entire structure.

Another important consideration is the material selection. Recent studies indicate that high-performance steel grades, such as S690, can offer enhanced yield strength and toughness. By choosing appropriate materials that align with the specific loading requirements and environmental conditions, engineers can ensure that the structural integrity remains intact over time. Maintaining a thorough understanding of the material properties and their behavior under various loads is essential for achieving long-lasting performance in steel structures.

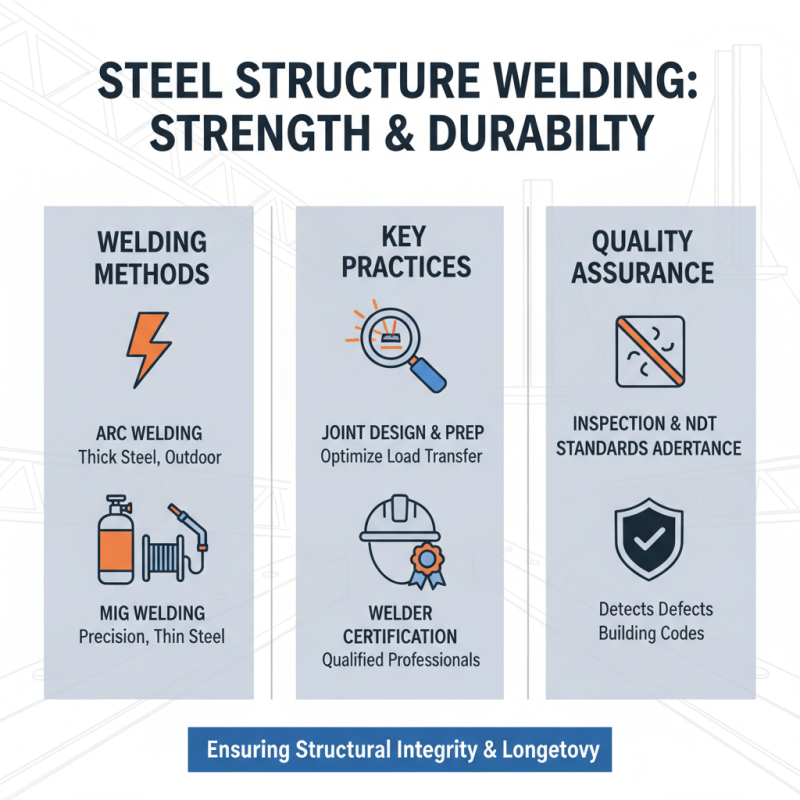

When constructing steel structures, the quality of weld and joint connections is paramount to ensure both strength and durability. One of the best practices is to choose the appropriate welding method for the specific application and environmental conditions. Techniques such as arc welding, MIG, and TIG each have their benefits and are suitable for different types of steel and thicknesses. Proper training and certification for welders are also essential to guarantee adherence to industry standards and to reduce the risk of defects that could compromise the integrity of the structure.

Additionally, pre-welding preparation plays a critical role in the overall strength of joint connections. This includes cleaning the surfaces to remove any contaminants, ensuring proper alignment of parts, and using correct filler materials that match the base metals. Post-weld treatments, such as heat treatment or stress relieving, are also recommended to alleviate any residual stresses and enhance the toughness of the welded joints. Regular inspection and maintenance of welded connections throughout the lifecycle of the structure can help in identifying issues early, ensuring ongoing safety and performance.

Regular maintenance plays a crucial role in enhancing the

longevity and performance of structural steel in construction.

According to a report by the American Institute of Steel Construction (AISC), regular inspections and preventive maintenance can

extend the lifespan of steel structures by up to 30%. Implementing a routine maintenance schedule can help identify

potential issues such as corrosion or fatigue before they become significant problems.

One effective maintenance strategy is to conduct thorough visual inspections annually, checking for signs of

rust, paint deterioration, and structural deformities. Additionally, applying protective coatings can significantly

enhance durability. A study published in the Journal of Construction Engineering and Management found that

structures with regular protective painting maintenance showed a 15% increase in service

life compared to those that didn’t.

For optimal strength and durability, it is also essential to involve proper load management.

Overloading can lead to structural failure, so understanding the load capacities and adhering to them is vital.

Regular maintenance and careful management not only ensure safety but also contribute to cost savings over time,

as reported by the International Journal of Steel Structures, which noted that proactive maintenance resulted in a

20% reduction in overall operational costs for steel construction projects.