Carbon Steel Pipe has emerged as a cornerstone in the construction industry, playing a crucial role in various applications ranging from structural frameworks to water distribution systems. According to a recent report by the Global Steel Pipe Association, the demand for carbon steel pipe is projected to grow by 4.5% annually through 2030, driven by infrastructure development and urbanization worldwide. This durable and versatile material is not only favored for its strength and cost-effectiveness but also for its adaptability in challenging environments.

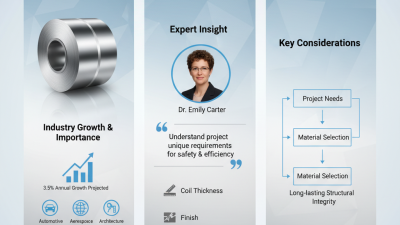

Industry expert Dr. Emma Harrison, a leading researcher at the Institute of Construction Materials, states, "Carbon Steel Pipe's resilience and structural integrity make it an essential component in modern construction." The manufacturing process of carbon steel pipes involves precise engineering techniques and stringent quality control measures, ensuring safety and performance across various applications. As cities expand and infrastructure ages, the importance of carbon steel pipe in meeting both current and future construction needs cannot be overstated.

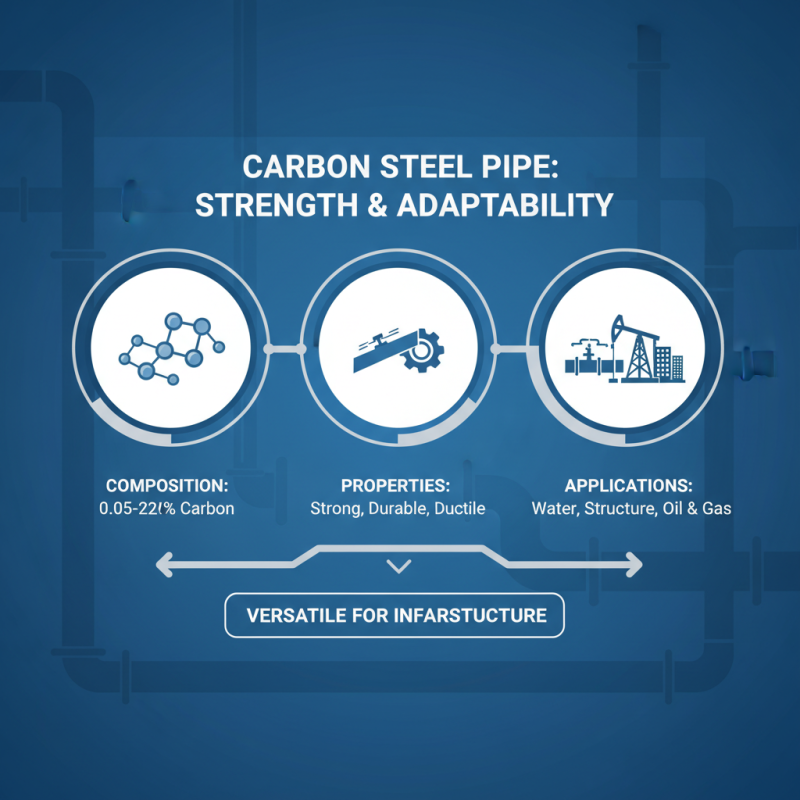

Carbon steel pipe is a type of pipe made from steel that contains a relatively low amount of carbon, usually between 0.05% and 0.25% by weight. This composition gives the steel significant strength and durability while maintaining good ductility, making it suitable for various applications in construction and infrastructure projects. The pipes can be manufactured in different grades, which determine their mechanical properties and suitability for specific uses, such as water transportation, structural framing, and oil and gas distribution.

The importance of carbon steel pipe in construction lies in its versatility and reliability. Due to its strength, carbon steel pipes can withstand high pressures and extreme environmental conditions, making them ideal for both above-ground and underground installations. Additionally, they are relatively easy to fabricate and can be welded, bent, or cut to meet the unique needs of any project. This adaptability, coupled with cost-effectiveness, ensures that carbon steel pipe remains a staple in the construction industry, supporting the development of infrastructure systems that are essential for modern society.

Carbon steel pipes play a crucial role in construction due to their strength, durability, and versatility. Different types of carbon steel pipes are used for various applications in the construction industry. The primary types include black steel pipes, which are typically used for transporting water, gas, and other fluids, and galvanized steel pipes, which have a protective zinc coating that helps prevent rust and corrosion. Structural steel pipes are another vital category, commonly utilized in building frameworks and heavy-duty applications.

When selecting carbon steel pipes for construction, it's essential to consider their properties and the specific requirements of your project. For instance, schedule 40 and schedule 80 pipes differ in wall thickness and pressure ratings, affecting their overall performance. Additionally, opting for seamless carbon steel pipes can provide improved strength and reliability in high-pressure systems.

Tips: Always ensure that the pipes meet relevant industry standards and codes to guarantee safety and efficiency. Regular inspections and maintenance can significantly extend the lifespan of carbon steel pipes, especially in environments prone to corrosion. Understanding the differences between each type of carbon steel pipe can help you make informed decisions that enhance the integrity and longevity of your construction projects.

| Type of Carbon Steel Pipe | Diameter (inches) | Weight (lbs/ft) | Applications |

|---|---|---|---|

| Seamless Carbon Steel Pipe | 1.5 | 1.68 | Oil & Gas Transportation |

| Welded Carbon Steel Pipe | 2.0 | 2.77 | Structural Support |

| ERW Carbon Steel Pipe | 3.0 | 5.01 | Construction and Manufacturing |

| Spiral Welded Pipe | 4.0 | 8.65 | Water and Sewage Systems |

Carbon steel pipes play a crucial role in construction projects due to their exceptional strength, durability, and versatility. According to a report by the Global Market Insights, the global carbon steel pipes market is expected to exceed USD 150 billion by 2026, driven primarily by the rising demand in construction. These pipes are further favored for their ability to withstand high pressure and temperatures, making them ideal for various applications, including structural frameworks, electrical conduits, and plumbing systems.

One of the most significant benefits of carbon steel pipes in building projects is their cost-effectiveness. Unlike other materials, carbon steel provides a favorable strength-to-weight ratio, allowing for lightweight designs without compromising structural integrity. The National Association of Manufacturers states that carbon steel pipes also contribute to sustainability efforts, as they are often recyclable and have a lower carbon footprint compared to plastic alternatives. Additionally, their resistance to corrosion and fatigue ensures a longer service life, reducing the need for frequent replacements and maintenance, which is vital for controlling project costs and timelines.

When selecting carbon steel pipes for construction projects, several critical factors must be considered to ensure optimal performance and longevity. One of the primary factors is the pipe's intended application. Different construction contexts, whether for structural support, transportation of fluids, or protection of electrical conduits, can necessitate specific attributes in the pipe, such as thickness, diameter, and grade. Understanding the specific requirements of the project helps in choosing a pipe that can withstand the environmental conditions and mechanical stresses it will encounter.

Another significant factor influencing the selection is the material's corrosion resistance. While carbon steel is known for its strength and durability, its susceptibility to rust can pose challenges in environments prone to moisture or harsh chemicals. Therefore, evaluating the environmental conditions where the pipes will be used is essential. In some cases, protective coatings or additional treatments may be necessary to enhance the longevity of carbon steel pipes in corrosive settings. Additionally, considering the ease of installation and welding capabilities can also influence the choice, as these characteristics directly impact labor costs and the overall efficiency of the construction process.

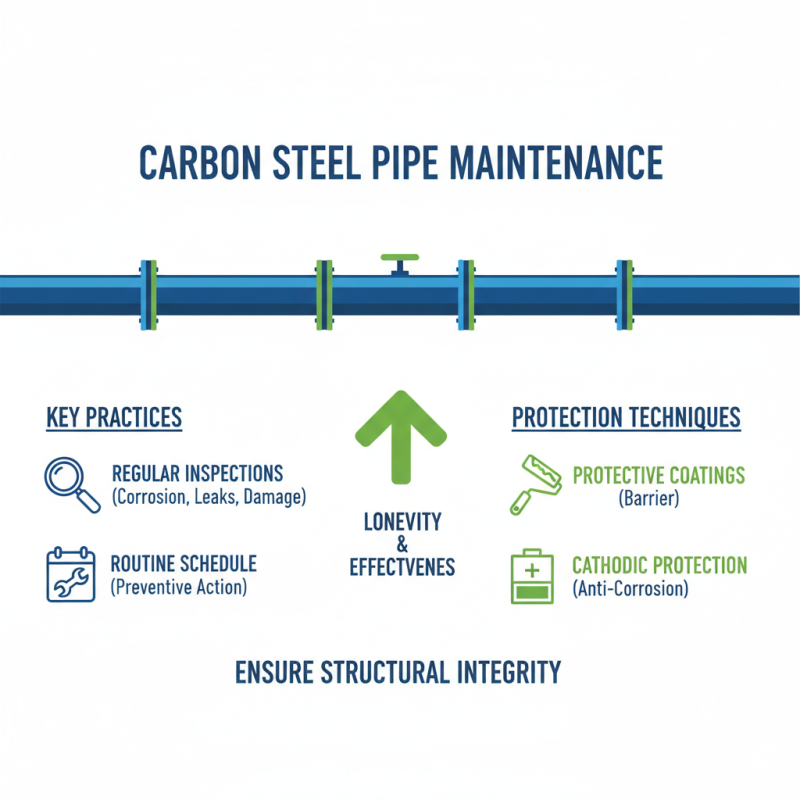

Maintenance of carbon steel pipes is crucial to ensure their longevity and effectiveness in construction applications. Regular inspections should be conducted to identify any signs of corrosion, leaks, or physical damage. Implementing a routine maintenance schedule can help in addressing minor issues before they escalate into significant problems that could compromise structural integrity. Techniques such as applying protective coatings and using cathodic protection can further enhance the lifespan of these pipes, preventing corrosion from environmental factors.

Longevity is significantly influenced by the environment in which carbon steel pipes are used. In corrosive environments, additional protective measures may be necessary. For instance, installing drainage systems to avert moisture accumulation or using insulation to protect against extreme temperatures can greatly prolong the service life of the pipes. Furthermore, selecting the appropriate type of carbon steel based on the specific construction needs can also play a pivotal role in minimizing maintenance requirements and enhancing durability, thereby ensuring that the pipes continue to function efficiently throughout their operational lifespan.