When selecting materials for construction projects, Galvalume Steel Coil stands out prominently. This innovative metal combines the strength of steel with a unique alloy coating, ensuring durability and resistance to corrosion. The benefits of using Galvalume Steel Coil extend beyond mere longevity; it also offers aesthetic appeal and versatility.

Many builders favor Galvalume Steel Coil for roofing and siding. Its lightweight nature makes installation efficient. Additionally, the reflective surface helps in reducing energy costs by keeping buildings cooler in hot climates. Yet, some may overlook potential challenges. The initial investment could be higher than traditional materials, which may raise concerns for budget-conscious projects. However, the long-term savings can outweigh these initial costs.

It is essential to consider the specific needs of each project. Galvalume Steel Coil may not always be the perfect solution for every application. Yet, for many, the advantages offered can be significant. Careful evaluation will lead to better decision-making in material selection. Ultimately, the choice hinges on balancing cost, longevity, and the specific requirements at hand.

Galvalume steel coil is a popular choice in construction and manufacturing. This material is known for its durability and resistance to rust, making it ideal for roofing and siding. It is composed of a unique blend of aluminum and zinc. This combination provides a protective coating that enhances the steel's longevity.

The aluminum component gives Galvalume its excellent weather resistance. It can withstand harsh conditions without corroding quickly. The zinc adds another layer of protection, ensuring that the steel remains strong and stable over time. This means fewer maintenance costs and longer service life for projects. Many builders appreciate the lightweight nature of Galvalume, which simplifies transportation and installation.

However, it's essential to be aware of some limitations. While Galvalume offers good corrosion resistance, it may not perform as well in highly acidic environments. Some users find that the finish can be less appealing if not properly maintained. Regular inspections and minor repairs can mitigate these concerns. Ultimately, understanding these characteristics can lead to more informed choices in material selection.

When it comes to construction materials, Galvalume steel coil stands out for several reasons. Its unique coating, which combines zinc and aluminum, provides superior corrosion resistance. According to a report from the American Galvanizers Association, projects using Galvalume can enhance lifespan by up to 50% compared to traditional galvanized materials. This durability is significant for structures exposed to harsh environments.

The aesthetic appeal of Galvalume is another advantage. It offers a sleek, modern finish that retains its look over time. Projects utilizing Galvalume have reported fewer maintenance issues and reduced repainting costs, contributing to long-term savings. However, improper installation could negate these benefits. This highlights the need for skilled labor in the application process.

Energy efficiency is also a critical factor. Galvalume reflects solar radiation, reducing cooling costs in buildings. Studies indicate that this can lead to energy savings of around 20%. Yet, not everyone recognizes its potential. Some developers overlook Galvalume, favoring other materials due to unfamiliarity. As construction evolves, it is crucial to stay informed about such innovative options.

| Advantages | Description | Application Areas |

|---|---|---|

| Corrosion Resistance | Galvalume steel coils have a protective layer that provides excellent corrosion resistance even in harsh environments. | Roofing, siding, and general construction. |

| Durability | Long-lasting performance with a lifespan typically exceeding that of standard galvanized steel. | Industrial buildings, warehouses, and outdoor structures. |

| Aesthetic Appeal | A smooth and appealing finish that can be painted or left bare for a modern look. | Residential buildings and commercial projects. |

| Cost-Effectiveness | Galvalume steel offers a lower total cost of ownership due to reduced maintenance needs. | Affordable housing and budget-sensitive projects. |

| Ease of Fabrication | Galvalume steel coils can be easily cut, shaped, and formed without significant loss of properties. | Customized metal components and various construction applications. |

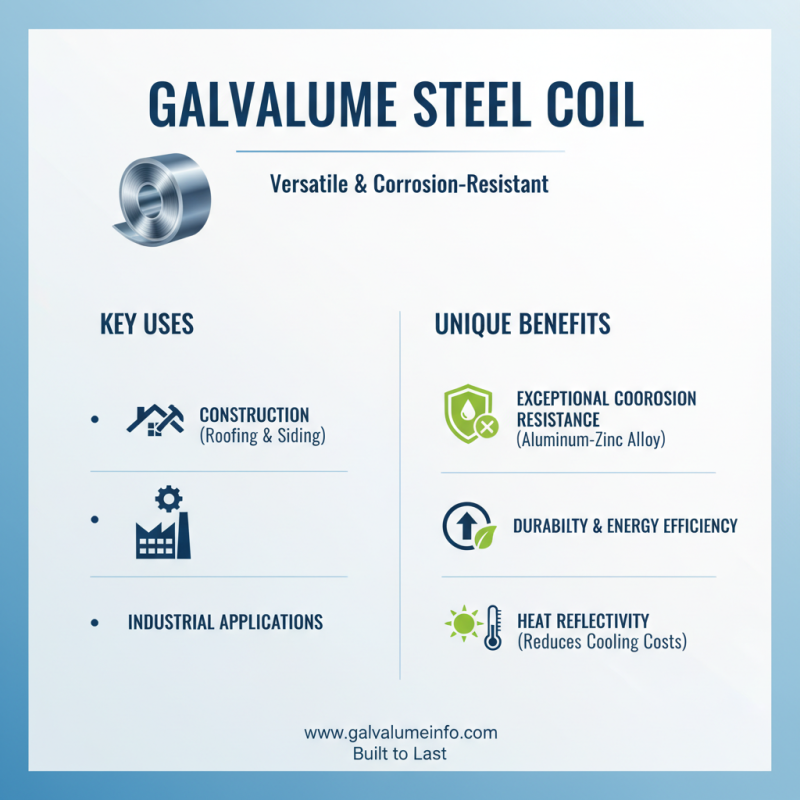

Galvalume steel coil is widely used across various industries due to its unique properties. The alloy coating of aluminum and zinc provides exceptional resistance to corrosion. It is a popular choice in construction, especially for roofing and siding applications. Buildings benefit from the durability and energy efficiency of Galvalume. Additionally, it can reflect heat, which helps in reducing cooling costs.

In the automotive industry, Galvalume is valued for its strength and lightweight characteristics. It is used in making parts that endure harsh weather conditions. The coil can be easily formed and welded. This adaptability is a significant advantage during manufacturing. Even with these benefits, some manufacturers may struggle with proper handling during installation. Mistakes here can lead to compromised performance.

Moreover, the appliance sector utilizes Galvalume for components exposed to moisture. Its longevity is an ideal fit for washing machines or refrigerators. However, not all designs maximize the coil's protective potential. Sometimes extra coatings may be necessary to enhance its performance in specific applications. Each industry must evaluate the specific conditions where Galvalume will be applied. Consideration is key to harnessing its full benefits.

When considering steel coatings, Galvalume steel stands out in several ways. Its innovative alloy of aluminum and zinc provides exceptional corrosion resistance. Studies have shown it offers up to 3-6 times more protection than traditional galvanized steel. This is especially vital in harsh environmental conditions. In coastal areas, for example, Galvalume can resist rust far better than other coatings, prolonging the lifespan of structures.

Tips: Always assess the environment where the material will be used. Galvalume performs well in humid and salty conditions. This makes it ideal for marine applications.

Moreover, the reflective properties of Galvalume contribute to energy efficiency. It helps reduce cooling costs in buildings. In the U.S., the Department of Energy notes that reflective surfaces can lower energy usage by up to 20%. However, while Galvalume excels in many areas, it can show scratches more visibly than some other options.

Tips: Regular inspections and maintenance can help address aesthetic concerns. Small blemishes do not compromise its performance, but keeping the surface clean is essential.

Galvalume steel coil is highly regarded for its maintenance benefits. According to a report from the Steel Recycling Institute, it offers a lifespan of up to 40 years. This longevity stems from a protective coating of aluminum and zinc. The combination prevents rust and corrosion effectively, reducing the need for frequent repairs.

However, not all applications experience the same durability. Exposure to extreme environmental conditions can still cause wear and degradation over time. For instance, in coastal areas, the salty air can lead to localized corrosion. Regular inspections are crucial. They help identify any signs of wear early and ensure that the material performs at its best.

The maintenance of Galvalume products is relatively straightforward. Most of the upkeep involves cleaning surfaces, which can simply be done with water and mild detergent. This ease is often appreciated in large-scale projects. Yet, it’s important to remember that neglecting maintenance can lead to unforeseen issues. Unexpected repairs can become costly and time-consuming if proper care is not taken.