When embarking on a project that requires metal sheets, selecting the right type can significantly influence the overall quality and performance of the final product. According to recent industry reports, the global metal sheet market is projected to reach approximately $350 billion by 2025, growing at a CAGR of 5.1% from 2020. This growth is driven by increasing applications across diverse sectors including automotive, aerospace, and construction, where the mechanical properties and versatility of metal sheets play crucial roles.

Metal sheets come in various materials such as aluminum, steel, and copper, each offering different characteristics suited for specific applications. For instance, aluminum sheets are known for their lightweight and corrosion-resistant properties, making them ideal for aerospace applications. Meanwhile, steel sheets are often selected for their strength and durability in construction projects.

Understanding these distinctions and matching them to your project's requirements is essential for ensuring efficiency, cost-effectiveness, and long-term satisfaction. As such, this guide will provide a comprehensive overview to help you navigate through the options and choose the right metal sheets for your needs.

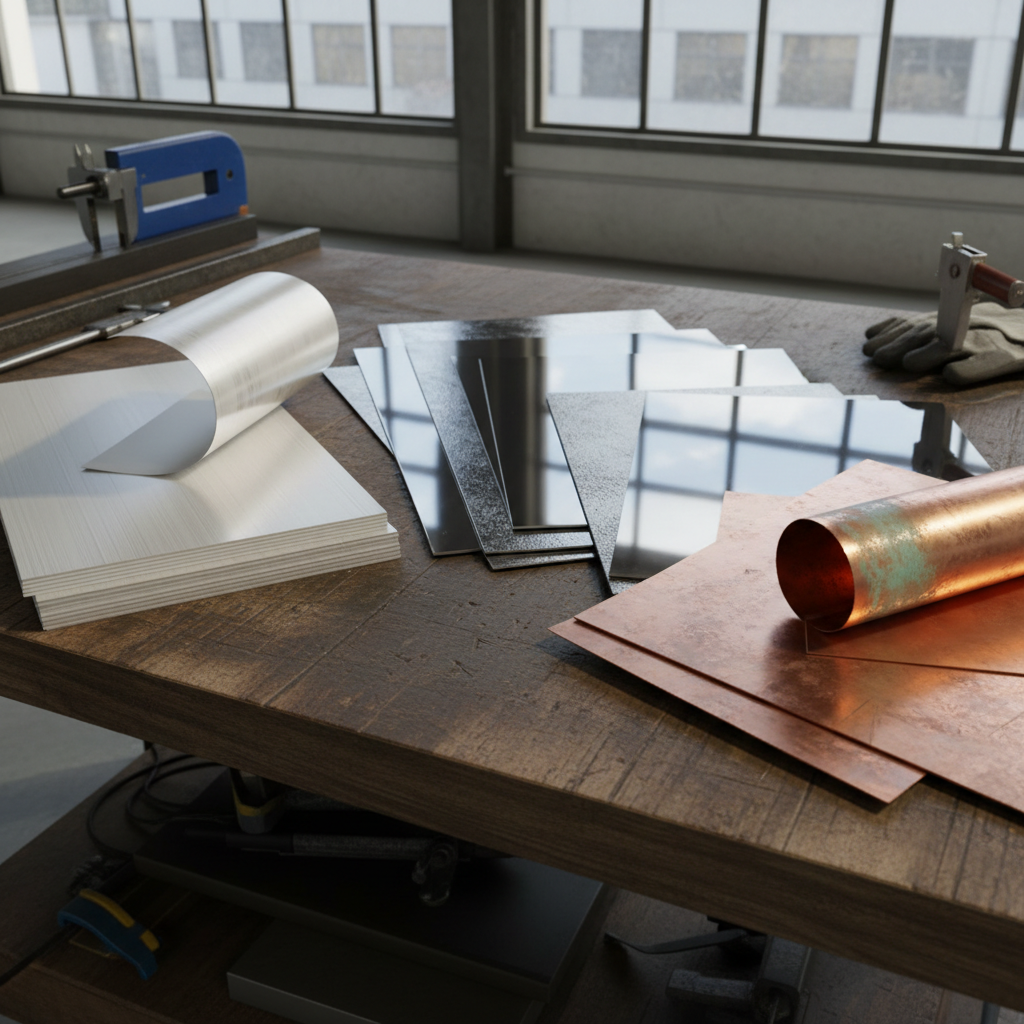

When embarking on a project that requires metal sheets, it’s essential to understand the different types available, as each offers unique properties that cater to specific needs. Common types of metal sheets include aluminum, stainless steel, and copper, each characterized by distinct benefits.

Aluminum sheets are lightweight and resistant to corrosion, making them ideal for applications ranging from automotive to aerospace. On the other hand, stainless steel sheets boast high strength and durability, suitable for heavy-duty environments and industrial applications.

In addition to these, other metal sheets like galvanized steel and brass also play important roles. Galvanized steel, coated with a layer of zinc, provides exceptional rust resistance, making it favorable for construction and outdoor applications. Brass, known for its aesthetic appeal and good corrosion resistance, is often used in decorative projects and plumbing. By understanding the characteristics and applications of these various metal sheets, you can make informed decisions that align with your project's requirements and ensure successful outcomes.

When selecting metal sheets for your projects, several key factors should be taken into account to ensure the best outcome. Firstly, the type of metal is critical; materials such as aluminum, steel, or copper each offer unique properties that suit different applications. Consideration should be given to factors like strength, weight, corrosion resistance, and thermal conductivity. For example, aluminum is lightweight and resistant to corrosion, making it ideal for projects needing a durable yet easy-to-handle material.

Another important aspect is the thickness and size of the metal sheets. Thicker sheets provide greater durability and load-bearing capabilities but may be more challenging to work with. It's essential to assess the requirements of your project and choose dimensions that align with your design specifications. Additionally, understanding the compatibility of the chosen metal with your existing tools and equipment can streamline the fabrication process, ensuring quality results. By carefully evaluating these factors, you can select the appropriate metal sheets tailored to your project’s needs.

When it comes to selecting metal sheets for your projects, thickness and weight play a critical role in determining the suitability of the material. Thicker metal sheets offer increased durability and strength, making them ideal for structural applications or situations where they will face heavy loads. Conversely, thinner sheets can be more manageable and easier to work with, making them a great choice for projects that require intricate designs or detail work.

**Tip:** Always consider the specific requirements of your project before choosing a thickness. If you're unsure, consulting with material suppliers can provide invaluable insights, helping you weigh the benefits and drawbacks of various options.

Weight is another important factor, especially if the metal sheet will be incorporated into larger structures or lightweight applications. Heavier sheets will offer more stability but could pose challenges regarding transport and installation. Light-weight alternatives may be preferable for ease of handling but may require additional reinforcement for structural integrity.

**Tip:** If weight is a concern, consider exploring alloy options. Many alloys are engineered to provide the strength of thicker gauge materials while remaining lightweight, thus offering the best of both worlds for your project requirements.

| Metal Type | Thickness (mm) | Weight (kg/m2) | Common Applications |

|---|---|---|---|

| Aluminum | 1.0 | 2.7 | Aerospace, Automotive |

| Stainless Steel | 2.5 | 7.9 | Kitchen Equipment, Construction |

| Mild Steel | 6.0 | 7.85 | Structurals, Fabrication |

| Copper | 0.5 | 8.96 | Electrical Applications, Plumbing |

| Titanium | 3.0 | 4.5 | Aerospace, Medical Devices |

When selecting metal sheets for various projects, understanding their common applications is crucial. Different types of metal sheets, such as aluminum, stainless steel, and copper, offer unique properties that make them suitable for specific uses. For instance, aluminum sheets are lightweight and corrosion-resistant, making them ideal for applications in aerospace and automotive industries. They are also commonly used in architectural features due to their aesthetic appeal.

On the other hand, stainless steel sheets are known for their strength and durability, making them a popular choice for kitchen equipment and medical devices. Their ability to withstand high temperatures and resist rust further enhances their application in various settings. Copper sheets, while less commonly used than the others, are prized for their excellent electrical conductivity, making them essential in electrical components and wiring.

Moreover, advancements in technology, such as 3D printing and electromagnetic methods for non-destructive evaluation, are expanding the possibilities in metal sheet applications. These innovations not only improve the efficiency of manufacturing processes but also allow for more tailored solutions in industries that require precise material properties. Understanding these nuances can greatly aid in making informed choices for any project involving metal sheets.

When selecting the right metal sheets for your projects, budgeting is a critical factor that goes beyond just the initial cost. Understanding the concept of cost versus value can help you make more informed decisions. While it may be tempting to opt for the cheapest option available, this can lead to higher long-term expenses due to factors like durability, maintenance, and performance. High-quality metal sheets that come with a higher price tag may save you money in the long run by offering better resistance to wear and tear, meaning less frequent replacements and repairs.

Furthermore, consider how different types of metal sheets can affect the overall value of your project. For instance, materials such as stainless steel may have a higher upfront cost but bring superior longevity and aesthetics compared to low-grade alternatives. By analyzing the total lifecycle costs, including installation and maintenance, you can determine which materials offer the best return on investment, ultimately leading to enhanced project viability and satisfaction.

Prioritizing value over sheer cost can be a game-changer in achieving both functionality and visual appeal in your metal sheet projects.