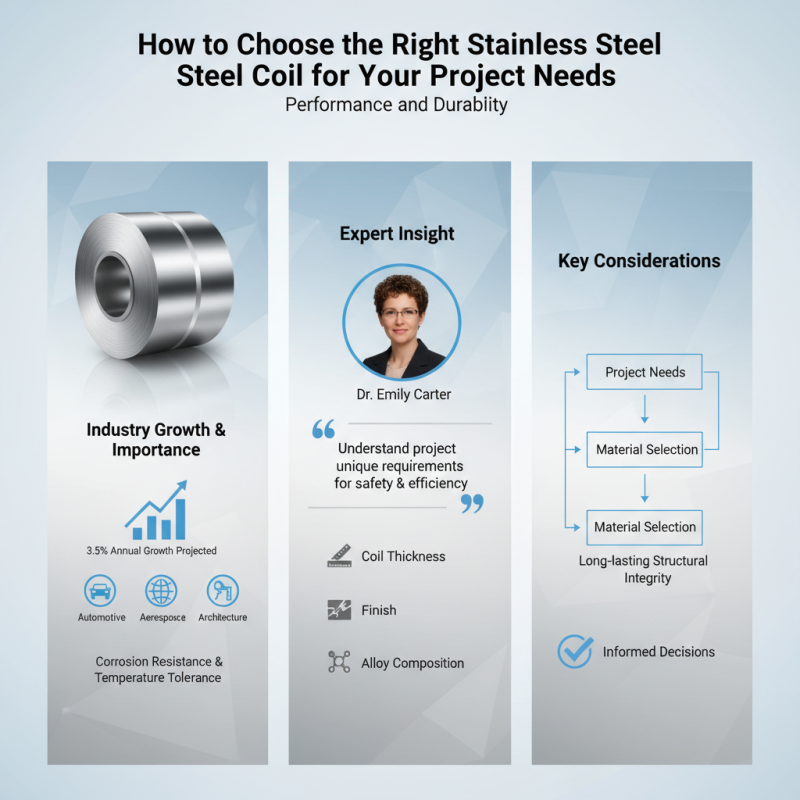

In the ever-evolving landscape of manufacturing and construction, selecting the appropriate Stainless Steel Coil for a specific project is pivotal to ensuring both performance and durability. According to a recent report by the International Stainless Steel Forum, the demand for stainless steel products, including coils, is projected to grow by 3.5% annually, underscoring the material's critical role in various industries such as automotive, aerospace, and architecture. This growth is driven by stainless steel's unmatched resistance to corrosion and its ability to withstand extreme temperatures, making it a preferred choice for a myriad of applications.

Renowned industry expert Dr. Emily Carter emphasizes the importance of making informed decisions in this regard, stating, "Choosing the right Stainless Steel Coil is not just about meeting technical specifications; it's about understanding the unique requirements of your project and selecting a material that enhances both safety and efficiency." With many options available, understanding key factors such as coil thickness, finish, and specific alloy compositions becomes essential for fabricators and engineers alike. With proper guidance and expertise, stakeholders can navigate the complexities of the market and select a Stainless Steel Coil that not only meets their project needs but also contributes to long-lasting structural integrity.

When selecting the right stainless steel coil for your project, it's essential to understand the different types available, as each type offers unique properties suited to various applications. The most common types of stainless steel coils include austenitic, ferritic, and martensitic steels. Austenitic stainless steel, characterized by its high chromium and nickel content, provides excellent corrosion resistance and is non-magnetic. It is often used in kitchens, food processing, and architectural applications due to its durability and aesthetic appeal.

Ferritic stainless steel coils contain higher chromium content and lower nickel levels, making them less expensive than austenitic options. They exhibit good corrosion resistance and are magnetic, which can be advantageous in specific applications. Ferritic coils are commonly used in automotive and industrial applications where moderate corrosion resistance and cost-effectiveness are priorities. On the other hand, martensitic stainless steel is known for its high strength and hardness, typically used in applications requiring wear resistance, such as cutlery and surgical instruments. Understanding these distinctions is crucial in making an informed decision that aligns with your project's specific needs and performance requirements.

When selecting stainless steel coils for your project, understanding the key properties of the material is crucial. One primary property to consider is corrosion resistance, which varies among different stainless steel grades. According to a report by the International Stainless Steel Forum, Austenitic stainless steels (like 304 and 316) are widely used due to their excellent resistance to rust and oxidation in various environments. This resistance makes them ideal for applications ranging from automotive to food processing industries.

Another important factor is the coil's thickness and width. The thickness of stainless steel coils typically ranges from 0.5 mm to 3 mm, with different thicknesses suitable for various applications. As reported by the Stainless Steel Development Association, proper thickness selection can significantly influence the performance and durability of your final product, especially in structural and industrial applications. Additionally, the coil's mechanical properties, such as yield strength and tensile strength, should match the specific requirements of your project.

Tips: Always consult with material specifications and standards relevant to your industry to ensure compliance. Additionally, it is beneficial to collaborate with suppliers who can provide detailed technical data sheets and advice tailored to your project needs. This proactive approach will help you make informed decisions and optimize the use of stainless steel coils in your applications.

When selecting the right stainless steel coil for your project, understanding the various factors that affect its performance is crucial. One of the primary considerations is the grade of stainless steel used, which directly influences corrosion resistance, tensile strength, and durability. Different grades offer varying levels of protection against environmental factors, such as moisture and chemicals, making it essential to analyze the specific conditions where the coil will be applied. For instance, a project exposed to aggressive substances may require a higher-grade stainless steel to ensure long-term performance.

Another key factor is the coil's thickness and gauge. The thickness can significantly affect the material's strength and its ability to withstand environmental stresses. Thicker coils generally provide better resistance to deformation and are more suitable for applications that experience heavy loads or extreme temperatures. Additionally, the manufacturing process, such as the method of rolling and finishing, can influence the surface quality and overall performance of the coil. A well-finished surface reduces the likelihood of corrosion and increases aesthetic appeal, which might be important for visible applications. Evaluating these factors carefully will ensure the selected stainless steel coil meets the project's specific requirements and longevity.

When evaluating the cost-effectiveness of stainless steel coils, it's essential to consider several key factors. First, the initial price of the coils can vary significantly based on material grade, thickness, and finish. Understanding the specific requirements of your project and how these variables influence the cost is crucial. It's advisable to compare quotes from various suppliers while also reviewing the specifications carefully to ensure that you’re not compromising on quality for a lower price.

Additionally, consider the long-term benefits and performance of stainless steel coils in your project. Stainless steel is known for its durability, corrosion resistance, and low maintenance needs, which can lead to substantial savings over time. By analyzing the lifecycle costs—factoring in installation, maintenance, and replacement expenses—you can better assess the total cost of ownership. A higher upfront investment may yield better overall value if it results in fewer repairs and longer service life. Thus, a thorough cost-benefit analysis can help you make an informed decision that aligns with your project’s financial goals while ensuring reliable performance.

When sourcing and purchasing stainless steel coils, it’s essential to consider various factors that align with your project needs. Begin by assessing the specific type of stainless steel required for your application, as different grades offer unique properties. For instance, according to a report by the International Stainless Steel Forum (ISSF), stainless steel grades 304 and 316 are highly sought after for their resistance to corrosion and durability in various environments. Understanding these properties can aid in selecting a coil that not only meets the industry standards but also enhances the quality of your final product.

Moreover, evaluating suppliers is crucial for ensuring that you receive high-quality materials at a competitive price. A recent industry analysis indicated that the stainless steel market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2028, driven by the expanding construction and automotive sectors. This growth translates to an increase in the number of potential suppliers, making it important to research their reputations, certifications, and product offerings. By asking for samples and examining the specifications of stainless steel coils before making a purchase, you can mitigate risks and ensure that your project requirements are met successfully.

| Dimension | Specification | Grade | Finish | Thickness (mm) | Market Price (USD) |

|---|---|---|---|---|---|

| 1000 x 2000 mm | ASTM A240 | 304 | Bright Annealed | 1.5 | $1500 |

| 1219 x 2438 mm | ASTM A240 | 316 | Matte | 2.0 | $1800 |

| 1250 x 2500 mm | ASTM A240 | Duplex 2205 | No. 1 | 3.0 | $2200 |

| 1500 x 3000 mm | ASTM A240 | 430 | 2B | 1.0 | $1300 |