In the realm of construction and manufacturing, the choice of materials can significantly impact the outcome of any project. Among these materials, Hot Rolled Steel Coils stand out for their versatility and strength. Expert metallurgist Dr. Emily Carter, a leading authority in the steel industry, notes, "Choosing the right type of Hot Rolled Steel Coils is crucial for ensuring both the durability and efficiency of your project." This assertion emphasizes the importance of making informed decisions when selecting steel products for various applications.

When embarking on a project that requires structural integrity, understanding the specific properties of Hot Rolled Steel Coils is essential. From weight considerations to thickness and yield strength, these factors can determine the effectiveness of the materials in use. Furthermore, the unique characteristics of Hot Rolled Steel Coils, such as their enhanced workability and excellent weldability, make them suitable for a myriad of applications, from bridges and buildings to automotive manufacturing.

Navigating the various options available in the market can be daunting, but with the right knowledge and expertise, one can confidently select the most appropriate Hot Rolled Steel Coils for their needs. This article aims to provide a comprehensive guide to help you make that critical choice, ensuring you achieve the best possible results for your project.

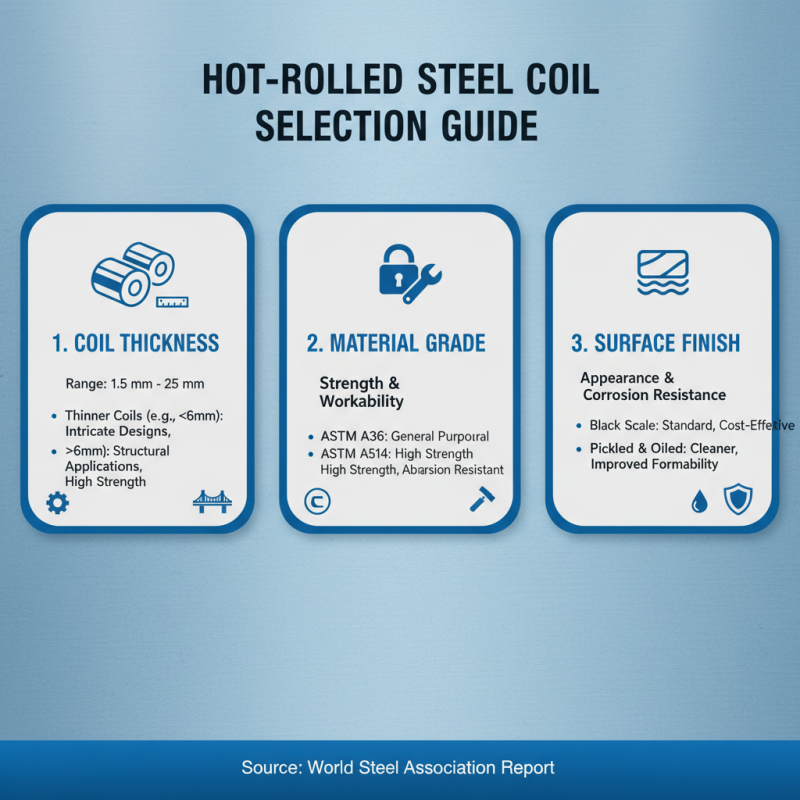

When selecting hot rolled steel coils for your project, it's essential to consider several critical factors that can impact both performance and cost. First, the thickness of the coils is a fundamental aspect; typical hot rolled steel thickness ranges from 1.5 mm to 25 mm. According to a report from the World Steel Association, the thickness affects the material's strength, workability, and final application compatibility. For instance, thinner coils may be more suitable for intricate designs requiring greater processing, while thicker coils are better suited for structural applications where strength is paramount.

Another crucial factor to consider is the chemical composition of the steel. Hot rolled steel typically contains varying levels of elements such as carbon, manganese, and phosphorus, which significantly influence the steel's mechanical properties. For example, a study by the American Institute of Steel Construction indicates that higher carbon content enhances tensile strength but may reduce ductility, affecting the ability to form and shape the material. It’s essential to choose a composition that aligns with the specific requirements of your project, including body style and load-bearing needs.

Lastly, understanding the manufacturing processes involved in producing hot rolled steel coils can significantly affect their quality and suitability for your application. The American Society for Testing and Materials (ASTM) provides guidelines on mechanical testing that can help you assess the quality and expected performance of the coils. Ensuring that the product meets these standards can guarantee that the steel will perform as required in demanding environments, ultimately leading to a more successful project outcome.

When selecting hot rolled steel coils for a project, understanding the specifications is paramount to ensuring optimal performance and compatibility with your requirements. Hot rolled steel is known for its versatility, and the specifications can vary significantly based on intended applications.

Key specifications include thickness, width, yield strength, and surface finish. For instance, according to the American Society for Testing and Materials (ASTM), a common range of thickness for hot rolled steel coils is between 0.093 inches and 0.750 inches, accommodating various construction and manufacturing needs.

Another critical factor is yield strength, which indicates how much load the steel can withstand before it deforms. Industry data reports indicate that standard yield strength values for hot rolled steel coils typically range from 220 MPa to 350 MPa, depending on the steel's chemical composition and processing methods.

Additionally, surface finish can influence the steel's usability in atmospheric conditions, with options including black oxide and pickled finishes, each affecting corrosion resistance and aesthetic qualities. By carefully evaluating these specifications, manufacturers and builders can ensure that the hot rolled steel coils they select will meet both the functional and structural demands of their projects efficiently.

When selecting hot rolled steel coils for your project, it's essential to understand the differences between various grades and types available in the market. Hot rolled steel typically comes in a range of grades that differ in chemical composition and mechanical properties. Common grades include ASTM A36, which is popular for its excellent weldability and versatility in construction applications, and ASTM A1011, known for its strength and ductility in machining and fabrication processes. Each grade serves specific purposes, so understanding the demands of your project is crucial when making a choice.

In addition to grades, hot rolled steel coils can vary in types, such as structural, commercial, and high-strength low-alloy steels. Structural steel coils are designed for construction and support, while commercial quality refers to materials that are more suited for general manufacturing or fabrication. High-strength low-alloy steels offer enhanced mechanical properties, making them ideal for demanding applications that require superior toughness and strength. By comparing these grades and types, you can ensure that the selected hot rolled steel coils meet the specific needs of your project and adhere to the required performance standards.

When evaluating the cost-effectiveness of hot rolled steel coils for your project, several factors come into play that can significantly impact your budget. The price of hot rolled steel has seen fluctuations in recent years, influenced by global supply and demand dynamics. According to the World Steel Association, the market price for hot rolled coil in early 2023 was approximately $700 per metric ton, a slight increase from $650 in 2022. Understanding such price trends is crucial for project planning, as securing materials at a lower price can lead to substantial savings.

Additionally, it’s essential to consider the total cost of ownership when selecting hot rolled steel coils. This includes not just the initial purchase price, but also considerations for processing and fabrication, which can account for up to 30% of the project’s overall cost, as reported in the Steel Construction Institute's latest data. Factors affecting processing costs include the grade of steel, required finishes, and any additional treatments. By analyzing these dimensions and conducting a thorough cost-benefit analysis, project managers can ensure that they are making informed decisions that balance quality and budgetary constraints, ultimately leading to a more economically viable project outcome.

| Coil Grade | Thickness (mm) | Width (mm) | Weight (kg) | Price per Ton ($) | Total Cost ($) |

|---|---|---|---|---|---|

| S235JR | 6 | 1000 | 6000 | 550 | 3300 |

| S275JR | 8 | 1200 | 9000 | 600 | 5400 |

| S355JR | 10 | 1500 | 12000 | 650 | 7800 |

| S420MC | 12 | 2000 | 15000 | 700 | 10500 |

When choosing hot rolled steel coils for your project, it's essential to focus on identifying reliable suppliers and evaluating their quality standards. Begin by researching potential suppliers who specialize in hot rolled steel. Look for companies with a solid reputation in the industry, as well as certifications that demonstrate their compliance with recognized quality standards. It can be beneficial to read customer reviews and case studies that highlight their experience and reliability. This preliminary research sets the foundation for a successful acquisition of materials that meet project specifications.

Once you've identified potential suppliers, the next step is to evaluate their quality standards. Inquire about their manufacturing processes and the raw materials they use. Quality control measures, such as testing for yield strength, thickness variations, and surface defects, are critical indicators of a supplier's commitment to excellence. Additionally, it is vital to check if they adhere to internationally recognized quality management systems, like ISO certifications. Transparency in their operations and willingness to provide product documentation can give you greater confidence in their products, ensuring that the hot rolled steel coils you choose will meet the demands of your project effectively.