Choosing the right steel plate for your project can seem daunting. With various types available, it's easy to feel lost. Industry expert John Smith once stated, "The right material can make or break your project." Understanding the specifics of steel plates is crucial.

Different projects require different grades and thicknesses of steel plates. Some plates are designed for structural support, while others are meant for aesthetic finishes. It's essential to consider the demands of your project carefully. For example, a high-stress environment needs a durable steel plate to ensure safety.

One common mistake is selecting a steel plate based on price alone. Often, cheaper plates can lead to future issues. Consider the long-term impact of your choice. Are you trading quality for savings? Reflecting on these questions can guide you to a better decision. Choosing wisely now can save time and resources later.

When selecting a steel plate, understanding the types available is crucial. Steel plates come in various grades and thicknesses. Common types include carbon steel plates, stainless steel plates, and alloy steel plates. Carbon steel plates are known for their strength and usability in construction and manufacturing. They are affordable but may rust if not coated. Stainless steel offers corrosion resistance and is ideal for kitchens and medical equipment. However, it can be expensive.

Alloy steel plates are versatile and can bear high stress. They are used in demanding applications, such as in oil and gas industries. Each type has specific properties and applications. Sometimes, choosing the wrong plate can lead to project delays or failures. It’s essential to consider the environment and the purpose of your project. Some plates are prone to rust, while others might not withstand extreme temperatures.

In addition to type, thickness matters greatly. Thicker plates can handle more weight but are harder to cut and weld. This can complicate the fabrication process. You may find yourself torn between quality and cost. Additionally, consider how you will transport and handle the plates. The right choice requires careful reflection on your project's needs and constraints. Balancing these factors can be challenging but is essential for success.

Choosing the right steel plate for your project involves various critical factors. The type of steel plate affects its strength and weight. Different grades offer unique properties. Mild steel is versatile but may lack durability in harsh conditions. Stainless steel resists rust but can be expensive. Assess the environment your project will face. Will it be exposed to moisture or chemicals?

Thickness is another crucial aspect. Thicker plates provide strength but add weight. Too heavy can complicate handling and increase costs. Balance is key. Next, consider size and shape. Custom dimensions might serve your needs but can lead to waste. Make sure to plan your cuts carefully to minimize scrap.

Surface finish should also factor into your decision. A smooth finish is easier to paint but may not be as robust. Rougher finishes can improve adhesion but may require more maintenance. Remember, choosing the right steel plate isn’t just about immediate needs, but also about long-term performance. Mistakes in selection can lead to costly repairs or project delays. Reflect on what truly meets your requirements.

| Factor | Description | Recommended Material | Typical Applications |

|---|---|---|---|

| Thickness | Thickness affects the strength and load-bearing capacity of the plate. | A36 Steel, A572 Steel | Construction, Structural components |

| Weight | Consider the overall weight for handling and transportation. | Aluminum, Steel | Automotive, Aerospace |

| Corrosion Resistance | Resistance to rust and corrosion is vital for longevity in harsh environments. | Stainless Steel, Weathering Steel | Marine, Outdoor structures |

| Grade | Different grades of steel offer varying levels of strength and ductility. | S235, S275, S355 | Heavy machinery, Fabrication |

| Finish | The surface finish can impact aesthetics and functionality. | Galvanized Steel, Painted Steel | Architectural elements, Fencing |

When selecting the right steel plate for your project, it's crucial to evaluate its specifications. Thickness, grade, and coating are essential factors. Steel plates come in various thicknesses, typically ranging from 1/8 inch to several inches. The choice often depends on the structural requirements. For instance, a thinner plate might suffice for lighter applications, while thicker plates are necessary for heavy-duty ones.

Grade is another critical aspect. Steel plates are classified into different grades based on their tensile strength and composition. For example, ASTM A36 is a common structural steel that offers good weldability and strength. Conversely, A572 offers higher strength with lower weight, which can be beneficial in specific applications.

Tips: Always check the material's mechanical properties before making a choice. Consider the environment in which the steel will be used. Corrosion-resistant coatings can significantly extend the life of the steel. Don't overlook the importance of proper storage; even quality steel can degrade if improperly stored. Remember, selecting the right specifications is vital. Make informed choices, and don't rush the decision-making process.

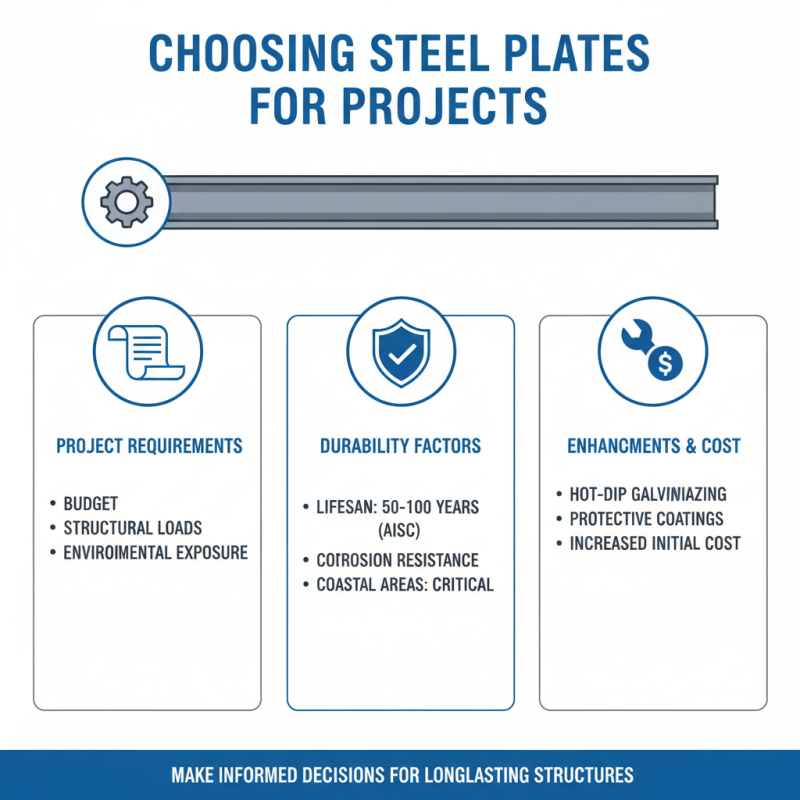

Choosing the right steel plate for a project requires careful consideration of project requirements. Durability is a critical factor. According to the American Institute of Steel Construction, the longevity of structural steel can range from 50 to 100 years, depending on environmental exposure. For projects located in coastal areas, corrosion resistance becomes essential. Hot-dip galvanizing or applying protective coatings can enhance durability but may raise initial costs.

Strength is another key requirement. Steel grades are crucial in this context. For example, ASTM A36 is common for general structural use and offers a yield strength of 36,000 psi. Higher grades like A992 provide greater strength, suitable for heavy structures. Engineers often overlook weight restrictions. Projects with limited load-bearing capacities must account for the steel’s weight. Using lighter options like high-strength low-alloy (HSLA) steels can provide similar performance while reducing overall mass.

Weight and strength balance can lead to unforeseen challenges. A thicker plate may promise more strength but becomes impractical if it exceeds weight limits. Each design decision must reflect the specific conditions of the intended application. Sometimes, further analysis is necessary to adjust choices in real-time. Adopting a flexible approach ensures optimal outcomes in the final design.

When considering steel plate for your project, cost and quality are crucial. A lower price may seem appealing, but it often comes at the expense of durability. Cheaper plates may corrode faster or bend under pressure. This can lead to extra costs down the line for repairs or replacements.

On the other hand, investing more upfront in high-quality steel can save money in the long run. High-quality plates offer better performance and longevity. This decision isn't easy. You must weigh immediate budget constraints against future expenses and project needs. Is a lower-cost option worth the risk of failure?

Sometimes, it helps to consult with experts. They can offer insights and recommendations based on experience. It's easy to get overwhelmed by choices and prices. Take your time to research. Don't hesitate to ask questions, even if it feels repetitive. Your project's success depends on these decisions, so think and reflect carefully.