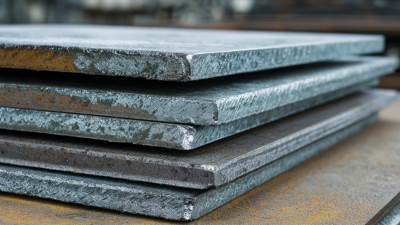

When embarking on a project that requires a Galvanized Plate, it is crucial to make informed decisions. The right choice can affect durability, performance, and cost. A Galvanized Plate serves various purposes, from construction to manufacturing. Understanding your project's needs is essential.

Selecting the appropriate Galvanized Plate involves assessing thickness, coating type, and dimensions. Each project has unique demands. Take time to evaluate what you truly need. Consider the environment where the plate will be used. Will it face harsh conditions or be indoors?

It's easy to overlook certain factors. Many assume all Galvanized Plates are the same. However, distinctions in quality and treatment exist. A poor choice might lead to rust or damage. Reflect on your options carefully. It’s important to ensure that your decision aligns with your long-term goals.

Galvanized plates are essential materials in construction and manufacturing. They are steel sheets coated with zinc to prevent corrosion. This coating makes them durable and long-lasting. Knowing the specifications of galvanized plates is crucial for making the right choice. Thickness, finish, and zinc coating weight are key factors to consider.

When selecting a galvanized plate, you should pay attention to its thickness. Thicker plates offer more strength but may be heavier and harder to work with. The finish also impacts aesthetics and adhesion for further processing, like painting. Additionally, consider the galvanization process—hot-dipped versus electro-galvanized. Each offers different levels of corrosion resistance.

It's important to reflect on your project's specific needs. What environment will the plate face? Will it be exposed to harsh conditions? Each project demands different specifications. Be aware that opting for seemingly cheaper options might lead to greater expenses in the long run if they fail. Striking a balance between cost, quality, and functionality is key in choosing the right galvanized plate.

When selecting a galvanized plate, several key factors come into play. First, consider the thickness of the plate. Thicker plates provide increased durability and corrosion resistance. Think about the project’s environment. Will it be exposed to harsh weather conditions? Heavier duty plates may be necessary in these cases.

Tip: Measure the area where the plate will be installed. This ensures you choose the right size for your specific needs. An ill-fitting plate can lead to excessive waste and costly mistakes.

Next, the intended use is crucial. Are you using it for structural support or decorative purposes? This will influence the quality and finish required. Sometimes, people overlook the finish. A smoother finish may be better for aesthetics but could compromise durability in certain settings.

Tip: Check the coating specifications. Some plates have a thicker coating for better longevity. Ignoring these details can lead to premature rusting.

Lastly, think about availability and delivery time. Do you need the plates quickly? Sometimes, this can force you to compromise on quality. Reflecting on all these aspects can lead to better decision-making for your project.

This chart illustrates the key factors that influence the selection of galvanized plates for projects, highlighting their relative importance in percentages. Understanding these factors can aid in making informed decisions when selecting the right galvanized plate.

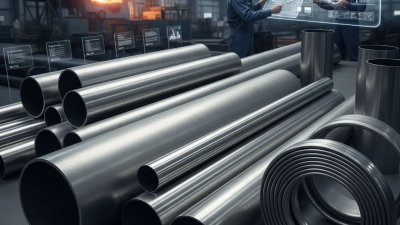

When selecting a galvanized plate, understanding corrosion resistance ratings is crucial. Various factors influence this rating, such as environmental conditions and material composition. A report from the American Galvanizers Association notes that a high zinc coating can significantly enhance corrosion resistance. For example, a thickness of 3.9 mils can provide protection for over 50 years in certain environments. However, this is not a one-size-fits-all solution.

Consider the application area. If the plate will be exposed to harsh chemicals or marine environments, a higher zinc thickness and supplementary coatings may be necessary. Data indicates that galvanized plates in rural areas experience less corrosion than those in urban settings due to lower pollution levels. Yet, even in seemingly protected areas, moisture can accelerate the corrosion process. Regular inspections and maintenance are essential.

It’s vital to assess cost versus longevity. Some projects may initially favor lower-grade galvanized plates for budget constraints. However, investing in higher-quality materials may prevent costly repairs down the line. A study reports that premature failures in corroded materials can lead to project overruns of up to 30%. Choosing the right plate means balancing immediate needs with long-term goals.

| Type of Galvanization | Corrosion Resistance Rating | Thickness (mm) | Common Applications |

|---|---|---|---|

| Hot-Dip Galvanized | Excellent | 2.0 | Construction, Outdoor Structures |

| Electro-Galvanized | Moderate | 1.5 | Indoor Furniture, Automotive Parts |

| Zinc-Aluminum Alloy Coated | Very Good | 2.5 | Industrial Equipment, Rooftop Structures |

| Galvannealed Steel | Good | 1.0 | Automotive and Appliance Parts |

| Mechanical Galvanizing | Good | 1.2 | Fasteners, Hardware |

Choosing the correct thickness and weight for galvanized plates is crucial for any project. Many industries, such as construction and manufacturing, rely on specific standards. Research shows that the most common thickness ranges from 0.5 mm to 3 mm for typical applications. Projects that require additional durability might check options above this range.

Weight also plays a vital role. A thicker plate generally weighs more, influencing transportation and installation costs. For example, a 1 mm thick galvanized plate usually weighs around 7.85 kg per square meter. Understanding these weight implications helps in budgeting and logistics.

Tip: Always calculate the weight before placing an order. Misjudging this can lead to unexpected challenges.

You may need to reflect on what thickness is necessary for structural safety versus aesthetics. In some cases, an overly thick plate can create a rigid appearance that conflicts with design intent. It’s important to balance both functionality and design needs.

Tip: Inquire about the tolerances for thickness you require. Not all suppliers have the same standards, which could affect your project’s outcome.

When selecting galvanized plates for your project, understanding industry standards and certifications is crucial. Galvanized plates often comply with ASTM, ISO, or EN standards. These regulations ensure quality and safety in materials. Look for plates that are hot-dip galvanized. This process offers better corrosion resistance than cold galvanizing. Certifications can help you determine the longevity of your plates.

Tips: Always check for certification logos. This often indicates adherence to safety and quality benchmarks. Inspect for proper coating thickness. A thicker layer usually means better protection against rust.

It's easy to overlook these details. Not all suppliers are upfront about their certifications. Sometimes, a product looks good but may not meet industry standards. This can lead to future failures or additional costs. Verify the information with reliable sources before making a purchase.