When embarking on a construction or manufacturing project, one of the crucial decisions you'll face is selecting the appropriate Steel Plate for your needs. Steel Plates are versatile materials used across various industries, including construction, automotive, and shipbuilding, due to their strength, durability, and ability to withstand harsh conditions. Understanding the various factors that influence the selection of Steel Plates can significantly impact the success and longevity of your project.

In this guide, we will explore the key considerations to keep in mind when choosing the right Steel Plate. Factors such as thickness, grade, and material properties play vital roles in ensuring that the selected Steel Plate meets the specific requirements of your application. Additionally, we will discuss how environmental factors and load-bearing capacities influence the type of Steel Plate that is most suitable for your project, enabling you to make an informed decision that aligns with your performance expectations and safety standards. Whether you’re working on a large-scale industrial project or a smaller fabrication task, the right choice of Steel Plate can lead to enhanced efficiency and effectiveness in your operations.

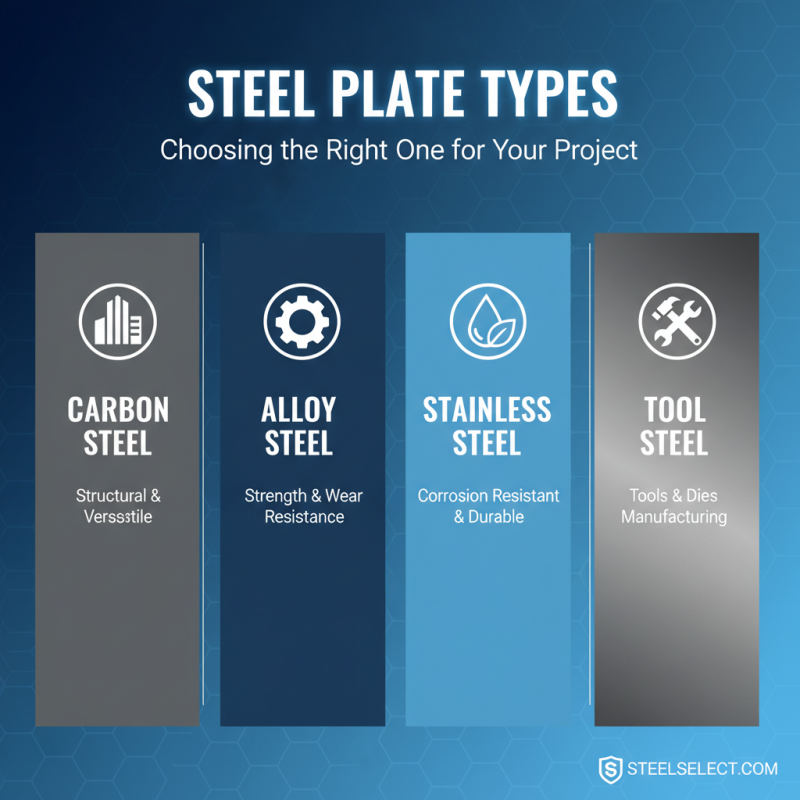

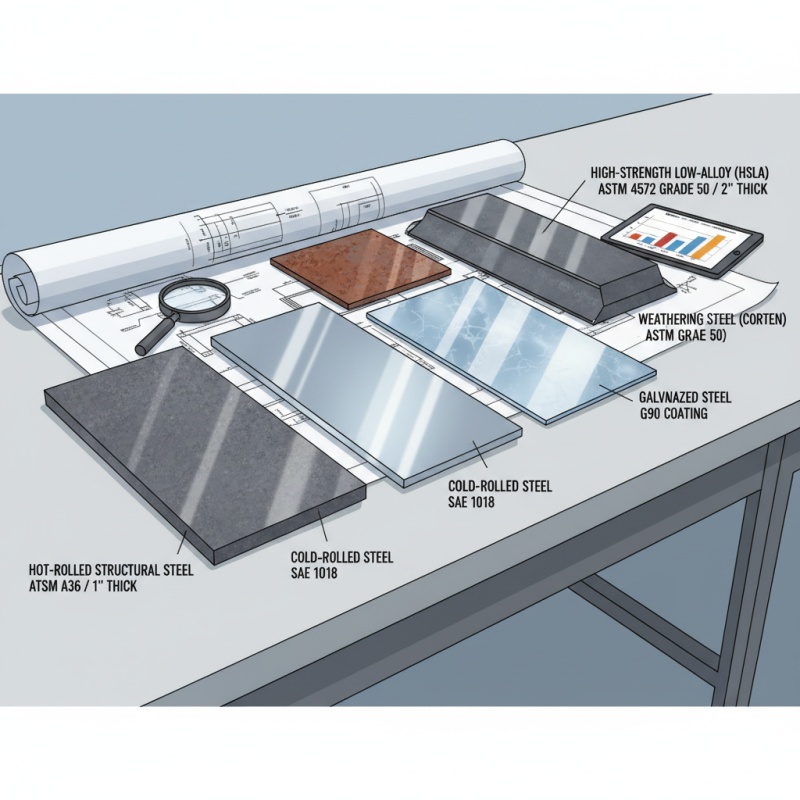

When selecting the right steel plate for your project, it's crucial to understand the different types available in the market. Steel plates vary widely in composition and application, with common types including carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is highly versatile and often used for structural applications, while alloy steel offers improved strength and resistance to wear. Stainless steel, known for its corrosion resistance, is ideal for projects requiring durability in harsh environments. Tool steel is specifically designed for manufacturing tools and dies.

Tips: Consider the environmental conditions your steel plate will face. For projects exposed to moisture or chemicals, opting for stainless steel can prevent rust and extend the life of the material.

Additionally, pay attention to the thickness and size of the steel plate. Thicker plates offer superior strength but may add unnecessary weight for some applications. Always match your choice with the specific demands of your project to ensure optimal performance and safety.

Tips: It can be beneficial to consult with a steel supplier or engineer who can offer guidance based on your project’s specifications, further enhancing your selection process.

When selecting steel plates for your project, several key factors should be taken into account to ensure that the material meets your specifications and functional requirements. First and foremost, understanding the type of steel—whether carbon, alloy, or stainless steel—is critical, as each type offers varying levels of strength, corrosion resistance, and machinability. According to the American Institute of Steel Construction, using the correct steel grade can enhance the performance and longevity of your structures significantly.

Moreover, thickness and dimensions are paramount considerations. The thickness of steel plates can directly influence the weight and strength of the final product. Reports by the Steel Manufacturers Association indicate that choosing the right gauge can save costs and enhance durability. For instance, a project requiring heavy-duty structural support may benefit from thicker, high-strength steel plates that bear heavy loads without deformation.

Tips: Always assess the environmental conditions your steel will face. For example, if your project is in a coastal area, consider corrosion-resistant grades. Additionally, think about how the steel will be fabricated and if weldability is a factor; certain grades are more conducive to welding and machining than others. Finally, sourcing steel from reputable suppliers ensures that you receive material that meets industry standards and specifications.

When selecting the right steel plate for your project, thickness and weight are pivotal factors that can significantly influence both performance and cost-effectiveness. The thickness of a steel plate typically ranges from 1/8 inch (3.2 mm) to several inches, depending on the intended application. According to the American Institute of Steel Construction, a plate’s thickness should be selected based on the load it must bear, with thicker plates providing greater resistance to bending, shear, and deformation. For structural applications, the use of plates with a minimum thickness of 1/4 inch is recommended in order to ensure sufficient strength and durability.

Weight considerations are equally important, particularly in applications where load limits and transport logistics come into play. For instance, a one-inch thick steel plate can weigh approximately 40 pounds per square foot, making it crucial to account for both the handling capabilities and the load-bearing infrastructure of the project site. The Metal Construction Association advises evaluating the total weight of steel plates in relation to the design of support structures to prevent potential overloading and failure. Proper calculations and planning around these specifications not only enhance safety but can also lead to cost savings by minimizing wastage and ensuring appropriate material procurement.

| Application | Thickness (inches) | Weight (lbs/sq ft) | Material Grade | Common Uses |

|---|---|---|---|---|

| Construction | 0.25 | 20 | A36 | Beams, Columns |

| Manufacturing | 0.5 | 40 | A572 | Machine Parts |

| Shipbuilding | 0.75 | 60 | A56 | Hull Construction |

| Welding | 0.375 | 30 | A500 | Structural Frames |

| Automotive | 0.125 | 10 | High Strength Steel | Chassis Components |

When selecting the right steel plate for your project, understanding the material properties of strength, durability, and corrosion resistance is essential. The strength of steel is a primary consideration, as it determines the plate's ability to bear loads and withstand stress. Steel grades vary significantly in tensile strength and yield strength, so it's crucial to choose a plate that can handle the specific demands of your application, whether it be structural support, industrial manufacturing, or fabrication.

Durability is another vital factor that must be evaluated. A durable steel plate will not only resist wear and tear but also maintain its structural integrity over time. This aspect is particularly important in environments subject to harsh conditions, such as extreme temperatures or mechanical wear. Considering the intended use of the steel plate will help you identify an option that remains reliable and effective throughout its lifespan.

Corrosion resistance is pivotal for projects exposed to moisture or corrosive elements. Steel plates can be treated or coated to enhance their resistance to rust and degradation, which is especially critical in outdoor applications or industries like marine construction. By understanding these material properties—strength, durability, and corrosion resistance—you can make an informed decision that aligns with your project's specific requirements, ensuring longevity and performance.

This chart illustrates the comparison of three important material properties of various types of steel plates: Strength, Durability, and Corrosion Resistance. Each property is assessed on a scale of 1 to 10 based on typical values for different steel grades.

When selecting steel plates for your projects, it’s essential to balance quality and budget effectively. The cost of steel can vary significantly based on factors like thickness, grade, and coating. While it might be tempting to opt for the cheapest option, this approach can lead to increased expenses down the line due to replacements or repairs. Therefore, investing in quality steel plates that meet your specific requirements may save money over time by ensuring durability and performance.

**Tips: When assessing quality, consider the steel plate's grade and certifications.** Higher grade steel often comes with better strength-to-weight ratios and corrosion resistance, making it a smart long-term investment. Additionally, evaluate your project's specific needs—if you require high performance in extreme conditions, a slightly higher upfront cost may be justified.

Another way to manage costs is to source steel plates in bulk or establish long-term relationships with suppliers. **Tips: Look for suppliers who can offer discounts for larger orders or repeating business.** This not only reduces the overall price but also ensures you have a reliable source for your materials, which is crucial for project timelines. Ultimately, balancing quality and budget begins with thorough research and precise needs analysis, setting the stage for a successful outcome.