In the world of manufacturing, Hot Rolled Steel Coils play a vital role. Renowned expert John H. Walker once stated, “Hot Rolled Steel Coils provide unmatched versatility for various applications.” This statement encapsulates their significance in construction and production.

Hot Rolled Steel Coils are made by rolling steel at high temperatures. This process enhances their malleability and reduces production costs. These coils are widely used in making structural components, automotive parts, and appliances. Their strength and durability are unmatched. However, the quality can vary, leading to potential issues in some applications.

While many manufacturers rely heavily on Hot Rolled Steel Coils, there are challenges. Not every batch meets the required specifications. Hence, choosing a reliable supplier is crucial. Miscalculations can lead to project delays and increased costs. Overall, Hot Rolled Steel Coils are fundamental in industry, yet careful consideration is necessary during their selection and use.

Hot rolled steel coils are a type of steel product produced by rolling steel at high temperatures. The process begins with heating steel slabs, allowing them to become malleable. Once heated, these slabs are passed through rollers, reducing their thickness to desired dimensions. The result is a flat, flexible product that is ideal for various applications.

These coils are often used in construction, automotive, and manufacturing industries. They are known for their strength and durability. The high-temperature rolling process can lead to some imperfections, such as surface roughness. These flaws can affect product quality in specific applications. However, many industries find that these imperfections do not hinder overall performance.

Applications for hot rolled steel coils include structural beams, automotive frames, and various machinery components. Some manufacturers prefer cold rolled steel for certain projects due to smoother surface finishes. Ultimately, the choice depends on the specific requirements of the final product. Companies need to weigh the benefits and drawbacks of using hot rolled steel coils.

The manufacturing process of hot rolled steel coils involves several critical steps. It begins with heating steel billets to a temperature exceeding 1,700°F (about 926°C). At this high temperature, the steel becomes malleable. Operators use large rollers to shape the steel into coils. This step is crucial as it determines the thickness and width of the final product.

After rolling, the steel undergoes rapid cooling. This cooling process can vary, impacting the final properties of the steel. It's often not perfect; variations can lead to inconsistent quality. Some coils might have surface imperfections or unwanted characteristics. These issues highlight the need for quality control during production. It’s important to inspect these materials carefully before use.

Additionally, hot rolled steel coils find numerous applications. They are widely used in construction, automotive, and manufacturing sectors. However, the choices made during the manufacturing process can affect their performance in these applications. Ensuring the right specifications is essential, but sometimes, mistakes happen. Learning from these errors improves future production rounds.

| Dimension | Applications | Manufacturing Process | Benefits |

|---|---|---|---|

| Thickness: 1.2mm - 25.4mm | Construction, Automotive Industry | Hot rolling process at high temperatures | High strength, good workability |

| Width: 600mm - 2000mm | Manufacturing of Machinery, Shipbuilding | Continuous casting and rolling | Cost-effective, uniform thickness |

| Weight: Up to 30 tons per coil | Structural beams, Piping | Rapid cooling during the process | Versatile applications, easy to transport |

| Finish: Black or Pickled | Heavy equipment, Storage tanks | Rolled at temperatures above recrystallization | Improved surface finish options |

Hot rolled steel coils are widely used in various industries due to their unique properties. One significant characteristic is their malleability. Hot rolling allows the steel to be shaped into large sheets or coils at high temperatures. This process reduces internal stresses, which gives the final product enhanced durability. The steel retains its strength but is much easier to handle and manipulate.

Another important property of hot rolled steel coils is their surface finish. The hot rolling process results in a rough surface texture, which can pose challenges for some applications. However, this roughness can improve adherence for coatings and paints. Its ease of production is appealing, making it a cost-effective option for manufacturers.

Despite these advantages, there are limitations. The dimensional tolerance of hot rolled coils might not meet the strict requirements for certain applications. They generally have wider tolerances compared to cold rolled steel. This can lead to complications in precision engineering tasks. The knowledge of these characteristics is essential for choosing the right material for specific needs.

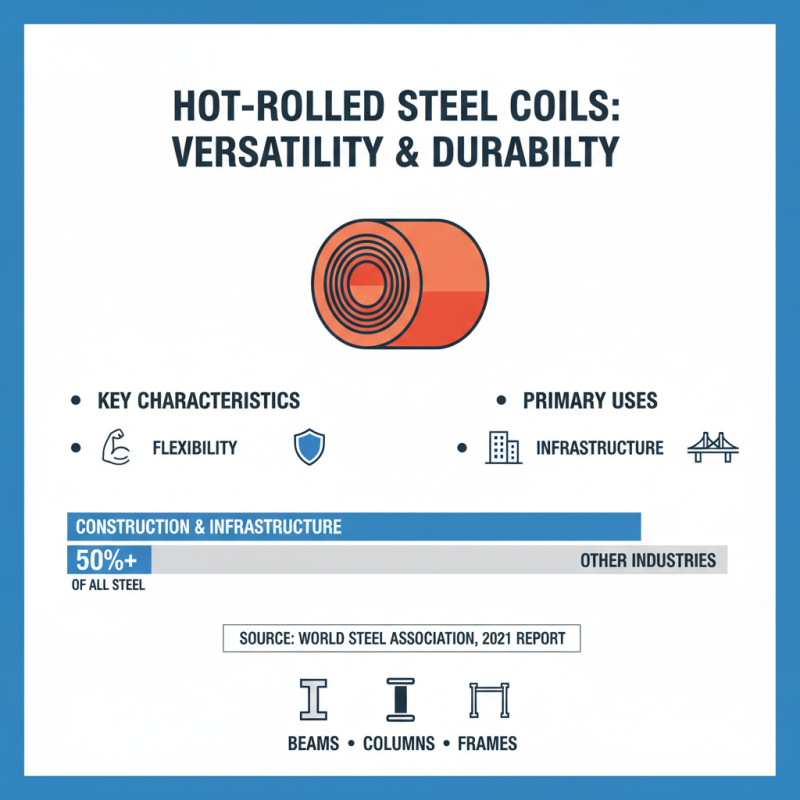

Hot rolled steel coils are widely used across various industries due to their flexibility and durability. In construction, these coils serve as structural components. A report by the World Steel Association in 2021 highlighted that more than 50% of steel is used in building and infrastructure. These coils contribute to creating beams, columns, and frames that support buildings and bridges.

In the automotive sector, hot rolled steel is crucial for manufacturing car bodies and chassis. The International Organization of Motor Vehicle Manufacturers noted that over 75 million vehicles were produced in 2020. Many utilize hot rolled steel for its strength and formability. However, the industry's reliance on these materials raises questions about sustainability and the environmental impact of steel production.

Additionally, the manufacturing of heavy machinery relies heavily on hot rolled coils. A 2020 analysis from the American Iron and Steel Institute suggested that machinery often uses 40% of the hot rolled steel produced. This statistic reveals the importance of these coils in various applications. Yet, challenges remain. The weight of hot rolled steel can sometimes limit its use in lightweight applications. These complexities highlight the need for further innovation in the industry.

Hot rolled steel coils are widely used in construction and manufacturing. They are made by rolling steel at high temperatures. This process gives the steel its strength and durability.

One advantage of hot rolled steel coils is their cost-effectiveness. They are cheaper than cold rolled steel. Additionally, the hot rolling process allows for larger sizes and weights. This is beneficial for structural applications. However, there are limitations. The tolerance levels are not as tight as cold rolled options. This can lead to more waste, especially in precise applications.

**Tip:** When choosing steel coils, consider the specific requirements of your project. It may save costs but could impact quality.

Another limitation is the surface finish of hot rolled steel. It tends to be rough and may require additional treatment. This could increase the overall project cost. Despite these factors, many industries prefer hot rolled steel for its versatility.

**Tip:** Always evaluate the end-use conditions of steel. This will help in selecting the right type for your needs.

This chart illustrates the various applications of hot rolled steel coils along with their percentage share in the overall market. Hot rolled steel coils are widely used in a variety of sectors due to their favorable properties.