Choosing the right round pipe for your project is essential in ensuring quality and durability. According to a report by the Global Pipe Manufacturers Association, the demand for round pipes is expected to grow by 5% annually. This growth highlights the importance of selecting the right materials and sizes for various applications.

Expert in the field, Dr. Julia Thompson, emphasizes, “Proper selection of round pipes can make or break a project’s success.” Understanding specifications is crucial. Specifications vary in size, thickness, and material type. Each of these factors influences performance and cost.

Many people overlook the nuances in pipe selection. A minor oversight can lead to major project delays or failures. Therefore, it is vital to gather all relevant information. Projects often face challenges that require careful consideration of every element. Failing to do so could be detrimental. The right choice in round pipes could ultimately affect project safety and efficiency.

When choosing the right round pipe for your project, it’s essential to understand the types available. Round pipes vary widely in material, size, and application. Common materials include PVC, steel, and copper. Each type has distinct properties, impacting your project’s durability and costs. PVC pipes are lightweight and resistant to corrosion. Steel pipes are sturdy but can rust if not treated. Copper pipes are often used for plumbing due to their reliability and long lifespan.

Consider the pipe's diameter, wall thickness, and pressure ratings. Smaller diameters suit low-flow applications. Larger pipes handle higher volumes but can be unnecessarily bulky. Wall thickness affects overall strength. A thicker wall provides more support but adds weight and cost. Always reflect on your project's specific needs. Sometimes, the most durable pipe isn’t the best choice for your budget or installation conditions. Aim to balance cost and performance.

Many projects also require compliance with local codes and regulations. Researching these guidelines can help avoid costly mistakes. It's tempting to focus solely on price, yet quality and suitability often outweigh initial savings. Take the time to evaluate all factors. Sometimes, the right choice is not the most obvious one.

Choosing the right round pipe for your project involves several key factors. One must first consider the material. Common options include steel, PVC, and aluminum. Each material has unique properties that affect durability and cost. For example, PVC is lightweight and resistant to corrosion. However, it might not withstand high pressure like steel does.

Another critical factor is the pipe diameter. Ensure that the diameter meets project specifications. A pipe that is too small can restrict flow. Conversely, a pipe that is too large can waste resources. Take time to calculate the required size based on the application. Pressure ratings are also essential. Not all pipes can handle the same pressure levels, which can lead to failures.

It’s crucial to examine the intended use. Will the pipes be exposed to extreme conditions? Reflecting on these details can prevent costly mistakes. Sometimes, the perfect pipe isn't available, making compromises necessary. Consider the project timeline and budget, as these factors also influence your choice. This complexity requires careful thought and may lead to some frustration.

When selecting the right round pipe for your project, material choice is critical. Steel pipes offer durability and strength. They resist high temperatures and are ideal for heavy-duty applications. However, they can be costly. Corrosion can also be an issue, requiring extra maintenance.

On the other hand, PVC pipes are lightweight and easy to install. They’re resistant to corrosion but can’t handle high temperatures. While they are affordable, PVC may not be suitable for all applications. In some cases, they might crack under pressure. Choices like aluminum or fiberglass also exist but come with their own pros and cons.

Ultimately, each option has strengths and weaknesses. Consider the specific requirements of your project carefully. Reflect on factors such as cost, durability, and environmental impact. It's important to weigh these aspects before making a decision.

| Material | Durability | Cost (per foot) | Weight (per foot) | Corrosion Resistance | Temperature Resistance |

|---|---|---|---|---|---|

| Steel | High | $5.00 | 1.5 lbs | Moderate | High (up to 1000°F) |

| PVC | Moderate | $0.90 | 0.5 lbs | High | Low (up to 140°F) |

| Aluminum | High | $3.00 | 1.0 lbs | High | Moderate (up to 600°F) |

| Copper | High | $4.50 | 0.8 lbs | Moderate | High (up to 1000°F) |

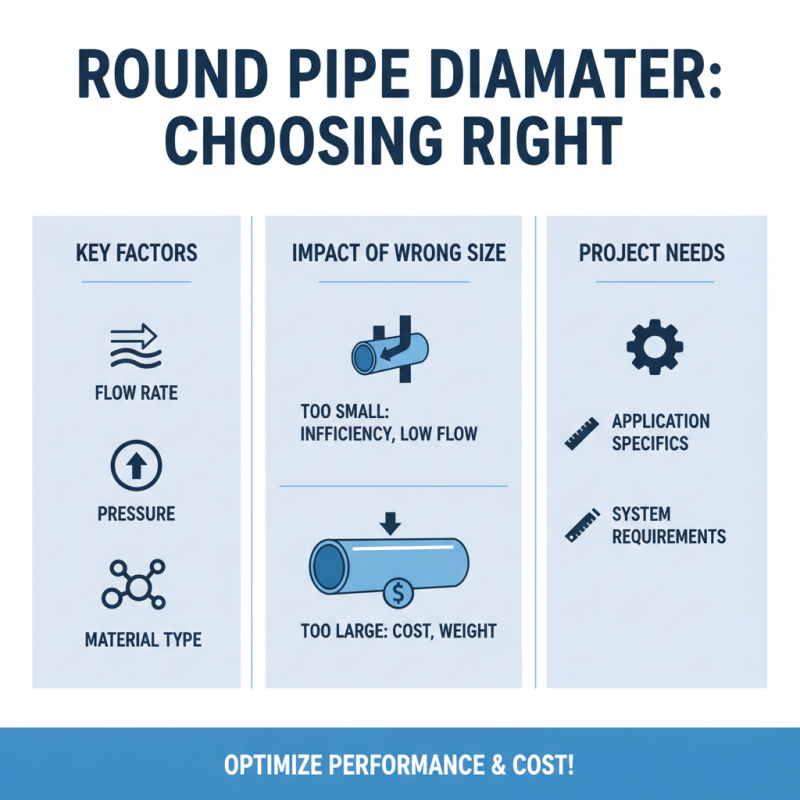

Choosing the right diameter for round pipes can be challenging. It’s essential to consider the specific requirements of your project. Factors like flow rate, pressure, and material type all play crucial roles. A pipe that is too small may lead to inefficiencies, while one that is too large can be unnecessarily heavy and expensive.

Start by assessing what you need the pipe for. Will it carry liquid or gas? What volume and speed are required? Make rough calculations. You might need more than you initially think. Sometimes, the ideal diameter feels too big. Trust the calculations.

Incorrect sizing can lead to costly errors. You might realize your initial choice doesn't fit. Ask for help if needed. Research different usage scenarios. Consider the environment where the pipe will be installed. Each situation is unique. Reflect on your choices and be open to adjustments as you go.

Round pipes are widely used in various industries, including construction, plumbing, and manufacturing. Their common applications depend on specific requirements. For instance, water supply systems often use round pipes made from PVC or PEX. According to a 2022 industry report, 45% of plumbing professionals favor PVC for its durability and cost-effectiveness.

In the construction sector, round pipes serve as structural elements. Steel pipes, for example, are essential in frame construction. They provide strength and can withstand heavy loads. An analysis showed that around 30% of construction projects demanded high-strength steel pipes to meet safety standards.

Choosing the right material and diameter is crucial. Inadequate sizing can lead to inefficiencies. Pipes that are too small may restrict flow, while oversized ones can waste resources. Some projects might require pipes with specific certifications. However, many professionals overlook these details, leading to costly mistakes. Understanding these requirements is vital for successful project completion.