When embarking on a construction project, selecting the right materials is crucial to ensuring success and longevity. Among the various options available, round pipe has emerged as a favored choice for many builders and engineers. This versatile material not only boasts a range of benefits but also finds application in diverse contexts—from plumbing and HVAC systems to structural frameworks.

The inherent properties of round pipe, such as its strength, resistance to wear, and ease of installation, make it an ideal candidate for projects that demand both durability and efficiency. Whether you are constructing a residential building or undertaking large-scale industrial work, understanding the advantages of round pipe can greatly inform your material choices. This article aims to delve into the myriad benefits and uses of round pipe, highlighting why it should be at the forefront of your next construction project.

When it comes to construction projects, the choice of materials can greatly influence both functionality and aesthetics. One of the standout choices is round pipe, which brings with it a plethora of benefits. Primarily, round pipes are known for their superior strength-to-weight ratio, which allows them to withstand high levels of pressure and stress. This characteristic makes them exceptionally useful in structural applications, where stability and durability are paramount. Additionally, their shape allows for even distribution of stress, reducing the likelihood of fractures or failures under load.

Beyond their structural advantages, round pipes are also highly versatile in terms of their applications. They can be used in plumbing, HVAC systems, and even in decorative architectural features. The smooth surface of round pipes facilitates easy flow, making them ideal for transporting liquids and gases efficiently. Furthermore, their circular cross-section can easily integrate with various fittings and junctions, simplifying installation processes. This adaptability not only enhances functionality but also contributes to streamlined construction timelines, ultimately leading to cost savings on projects.

Round pipes are widely utilized across various industries due to their structural integrity and versatility. Their cylindrical shape allows for efficient fluid flow and minimizes pressure loss, making them ideal for plumbing and HVAC systems. In the construction industry, round pipes are typically employed in water supply and drainage systems, where their smooth interior surfaces help prevent clogs and ensure consistent water flow. Additionally, their strength makes them suitable for structural applications, such as scaffolding and support beams, which are essential for maintaining the stability of buildings and other constructions.

Beyond construction, round pipes find significant applications in the oil and gas sector, where they are used for transporting hydrocarbons. Their robust construction can withstand high pressures, making them ideal for delivering petroleum products from extraction sites to processing facilities. Similarly, in the transportation industry, round pipes serve as essential components in vehicle exhaust systems, enabling efficient emission control. Their adaptability also extends to industries such as agriculture and manufacturing, where they are used in irrigation systems and conveyor mechanisms, respectively, demonstrating their multifaceted benefits and expansive range of uses.

| Industry | Applications | Benefits of Round Pipe | Common Materials |

|---|---|---|---|

| Construction | Structural frameworks, plumbing | Strength, durability, versatility | Steel, PVC, Copper |

| Manufacturing | Conveyor systems, machinery parts | High load capacity, ease of replacement | Aluminum, Stainless Steel |

| Oil and Gas | Pipelines, drilling equipment | Corrosion resistance, high tensile strength | Carbon Steel, Alloy Steel |

| Automotive | Exhaust systems, roll cages | Lightweight, structural integrity | Mild Steel, Titanium |

| Aerospace | Fuel lines, frame components | High strength-to-weight ratio, reliability | Aluminum, Composite materials |

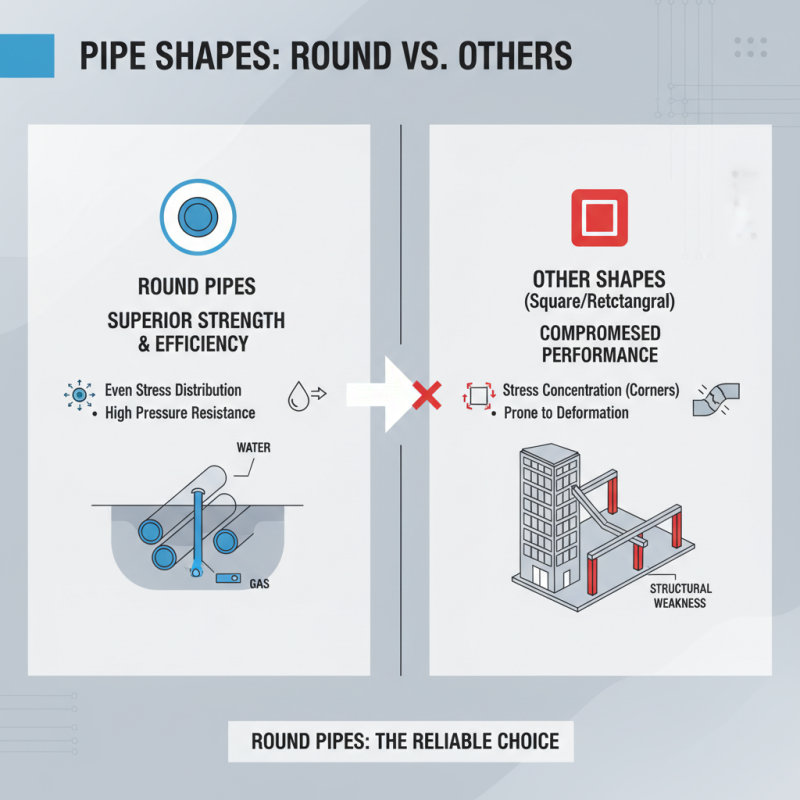

When considering various pipe shapes for construction projects, the choice between round pipes and other alternatives can significantly influence the overall performance and efficiency. Round pipes are known for their structural integrity and ability to withstand internal and external pressures. Unlike square or rectangular pipes, which may experience stress concentration at the corners, round pipes distribute loads evenly across their surfaces, making them less prone to deformation under heavy loads. This characteristic is particularly beneficial in applications requiring durability and reliability, such as in water and gas distribution systems.

In contrast to other shapes, round pipes also offer superior flow efficiency due to their geometric design. The circular interior minimizes turbulence and friction, facilitating smooth fluid movement. Square or rectangular pipes, on the other hand, can create more resistance within the fluid flow, potentially leading to reduced efficiency in transporting liquids or gases. Furthermore, round pipes tend to be lighter and easier to install, allowing for a more streamlined construction process. This advantage becomes particularly evident in large-scale projects, where the ease of handling can lead to significant time and cost savings. Overall, round pipes present a compelling option when comparing different shapes for construction applications.

When selecting materials for construction projects, round pipes offer a unique set of properties that enhance durability and performance. One of the most significant benefits of round pipes is their structural integrity. Their uniform shape allows for even distribution of stresses, which makes them less likely to deform under heavy loads. This characteristic is particularly advantageous for applications such as plumbing, structural supports, and framework, where strength and reliability are paramount.

Additionally, round pipes are resistant to corrosion, especially when treated appropriately. This resistance contributes to their longevity and reduces the need for frequent replacements, saving both time and resources over the life of a project. These pipes can also withstand extreme weather conditions, making them suitable for outdoor applications.

Tips: When choosing round pipes, consider the environment in which they will be used. If corrosion is a concern, opting for galvanized or stainless steel round pipes may enhance durability. Furthermore, ensure that the dimensions and thickness of the pipes match the specific load requirements of your project to maximize their effectiveness. Regular inspections and maintenance can also extend the lifespan of round pipes, ensuring they continue to perform at their best throughout their usage.

When it comes to installing round pipes in construction, several techniques ensure optimal performance and durability. One effective method is the use of seamless steel pipes, which significantly reduces the risk of leaks and joint failures. According to a report by the American Society of Civil Engineers, seamless pipes can reduce installation time by up to 30% compared to traditional welded options due to their strength and reliability. The absence of seams means fewer points of potential weakness, making these pipes ideal for high-pressure applications.

Additionally, proper alignment and support during the installation process are crucial. Installing round pipes on a level foundation with adequately spaced supports not only helps in maintaining the integrity of the structure but also complies with building codes. The National Pipe Support Association suggests using supports spaced no further than 10 feet for pipes carrying heavy loads, ensuring safety and efficiency in the installation process. Furthermore, incorporating technologies such as laser scanning during installation can enhance precision, leading to improved overall project timelines and reducing costly rework.

Overall, understanding these installation techniques facilitates the effective use of round pipes in various construction applications, ensuring they meet the required performance standards while adhering to best practices in safety and efficiency.