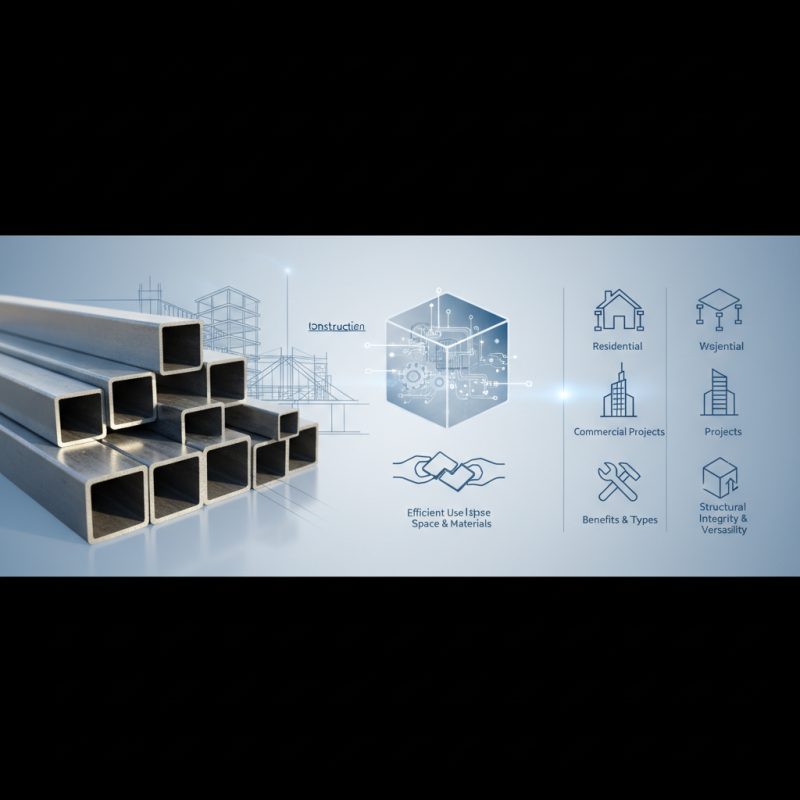

In the construction and manufacturing industries, the significance of material selection cannot be overstated, and one notable choice that has gained traction is the square pipe. Square pipes, known for their structural integrity and versatility, are essential in a myriad of applications. According to John Smith, a leading expert in metal fabrication, “Square pipes combine strength with adaptability, making them a preferred option for modern engineering projects.” This statement highlights the fundamental advantages that square pipes offer to various sectors.

Square pipes are utilized in everything from architectural frameworks to infrastructure support, demonstrating their broad functionality. Their unique shape allows for efficient use of space and materials, making them not only economical but also practical for various design considerations. Furthermore, as industries evolve, the demand for innovative and reliable piping solutions grows, positioning the square pipe as a vital component in both residential and commercial projects.

In this article, we will explore what square pipes are, delve into their diverse applications, examine their benefits, and outline the different types available. Understanding these aspects is crucial for anyone involved in design and construction, as square pipes continue to play an indispensable role in shaping our built environment.

A square pipe, commonly referred to as a

hollow section, is a type of structural element

characterized by its four equal sides and a hollow internal space. This shape not only provides

strength and stability but also allows for a lightweight solution in various construction and

manufacturing applications. Square pipes are typically made from materials like steel,

aluminum, or plastic, making them versatile for diverse

environments, including structural frameworks, furniture, and piping systems.

One notable attribute of square pipes is their ability to distribute stress evenly across all sides.

According to a report by the Steel Construction Institute, square hollow sections exhibit greater

resistance to bending and torsional forces compared to their round counterparts, making them ideal for

applications such as beams, columns,

and supports in construction. Additionally, their uniform shape

allows for easier stacking and handling, contributing to reduced manufacturing costs and increased

efficiency in logistics.

Furthermore, the use of square pipes is expanding in sectors such as automotive

and furniture design due to their sleek aesthetic and functional flexibility.

A study by the European Committee for Standardization highlights that the demand for lightweight structural

materials, including square pipes, is projected to grow by 5% annually as

industries increasingly focus on efficiency and sustainability. This shift underscores the

significant role that square pipes play in modern engineering and design, catering to both

aesthetic preferences

and practical requirements.

Square pipes, also known as square tubes, are vital components in various industries due to their unique structural properties and versatility. Commonly used materials for square pipes include steel, aluminum, and various types of plastics. Steel square pipes, particularly those made from carbon steel, are renowned for their strength and durability, making them suitable for heavy-load applications in construction and manufacturing. According to a report by the International Stainless Steel Forum (ISSF), the global demand for square steel pipes is projected to grow by around 4% annually, primarily driven by infrastructure expansion and urbanization trends.

Aluminum square pipes, on the other hand, offer a lightweight alternative and excellent resistance to corrosion, making them popular for applications in the automotive and aerospace industries. The Aluminum Association reports that aluminum’s lightweight properties can reduce overall vehicle weight by approximately 20-30%, leading to increased fuel efficiency. Lastly, plastic square pipes, such as those made from PVC or HDPE, are gaining traction in agricultural and drainage applications due to their resistance to chemicals and easy installation. The versatility of materials used for square pipes allows for tailored solutions across various sectors, underscoring their importance in modern engineering and manufacturing practices.

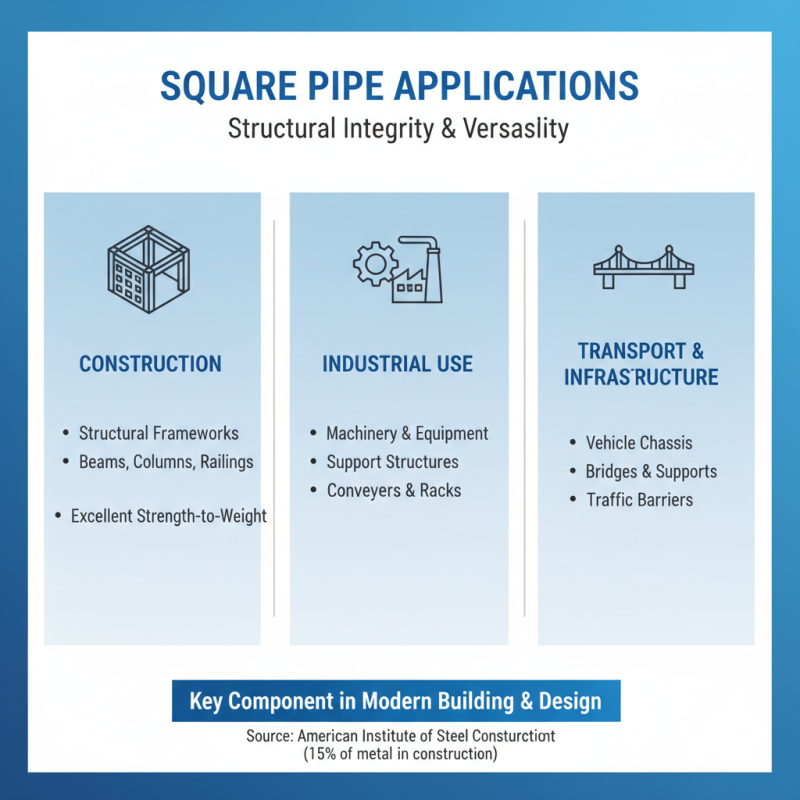

Square pipes, known for their structural integrity and versatility, find extensive applications across various industries. In construction, square pipes are favored for structural frameworks, providing excellent strength-to-weight ratios. According to a report by the American Institute of Steel Construction, square and rectangular tubes account for nearly 15% of metal used in construction projects, highlighting their importance in building robust structures. Their uniform shape allows for seamless integration with other materials, making them ideal for beams, columns, and railings.

In the HVAC industry, square pipes are essential for ductwork systems. The uniform cross-section of square pipes minimizes turbulence and enhances airflow efficiency, resulting in improved energy performance. A study conducted by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that duct systems using square pipes can increase energy efficiency by up to 20%. Additionally, square pipes are utilized in manufacturing industries for pipelines and conveyors, where their rigidity and adaptability to various loads play a crucial role in operational efficiency. Practical applications, such as in automotive manufacturing, showcase the versatility of square pipes, not only in conveying materials but also as protective casings and support structures.

Square pipes, characterized by their equal width and height, offer several advantages over their round or rectangular counterparts. One of the primary benefits of utilizing square pipes is their structural integrity. The uniform shape ensures that stress is distributed evenly throughout the pipe, making them ideal for construction projects where stability and support are paramount. This even load distribution minimizes the risk of deformation, enhancing the longevity of the structures built with these materials.

Another significant advantage is the ease of handling and installation. Square pipes can be easily stacked and aligned due to their straight edges, which facilitates efficient transport and storage. Additionally, the corners of square pipes allow for secure fastening and welding, making them a preferred choice in many fabrication applications. Their versatility is another compelling reason; square pipes can be used in a wide array of applications ranging from furniture manufacturing to automotive frames, providing aesthetic appeal and robust functionality. As such, their adaptability and inherent advantages make square pipes a go-to option for various industrial and commercial uses.

| Dimension (mm) | Material | Applications | Benefits |

|---|---|---|---|

| 25 x 25 | Mild Steel | Furniture, Railing | High Strength, Easy to Weld |

| 50 x 50 | Stainless Steel | Construction, Automotive | Corrosion Resistance, Aesthetic Appeal |

| 75 x 75 | Aluminum | Frames, Structures | Lightweight, Durable |

| 100 x 100 | Galvanized Steel | Transport, Storage | Rust Protection, Versatility |

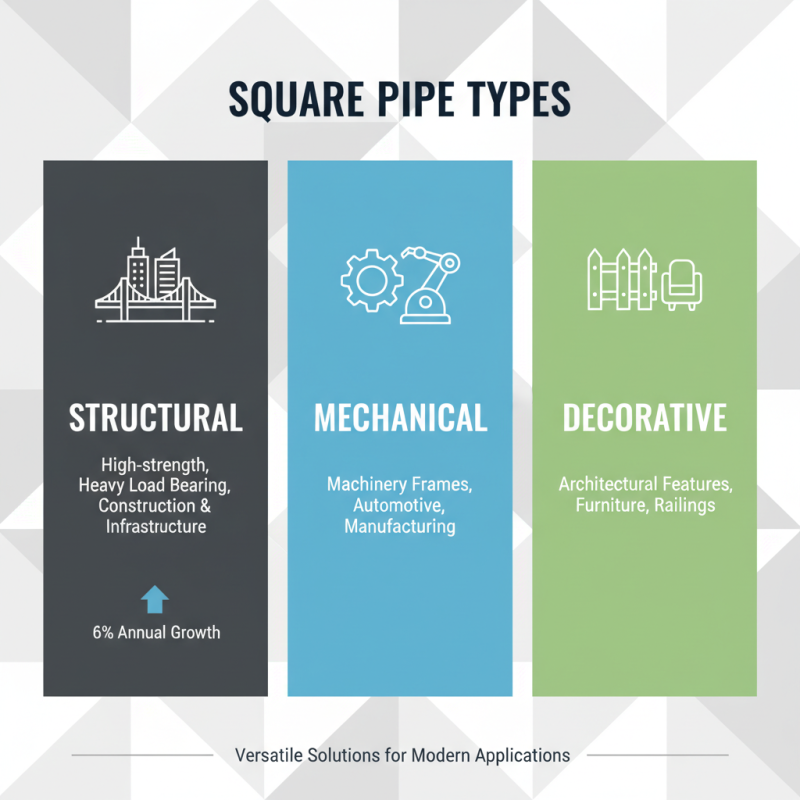

Square pipes, also known as square tubing, come in various types that cater to a wide range of applications. The most common types include structural square pipes, mechanical square pipes, and decorative square pipes. Structural square pipes are often made from high-strength materials and are commonly used in construction and infrastructure projects due to their ability to bear heavy loads. According to industry reports, the use of structural square tubing in construction has seen a growth rate of over 6% annually, reflecting the rising demand for durable building materials.

Mechanical square pipes, on the other hand, are primarily used in manufacturing and industrial applications. These pipes are designed to withstand high pressure and are often utilized in hydraulic systems and machinery. Specifications for mechanical square pipes usually include standards for tensile strength and resistance to flaring, which ensure their reliability under operational stress. For instance, many mechanical square pipes are produced following ASTM A500 standards, which specify minimum yield strength requirements, ensuring high performance.

Finally, decorative square pipes, often used in furniture and architectural designs, emphasize aesthetics while maintaining structural integrity. These are typically manufactured in a range of finishes and coatings to enhance their visual appeal and resistance to corrosion. Market analysis indicates an increasing trend in the use of decorative square tubing in contemporary designs, with an expected market growth of around 4% in this segment as aesthetics become a significant factor in material selection. With their diverse applications and tailored specifications, square pipes continue to play a crucial role in various industries.