As we move toward 2025, the landscape of the steel industry is evolving rapidly, driven by innovation and shifting market demands. One of the key segments experiencing significant changes is the production and application of Hot Rolled Steel Coils. These versatile materials are critical in a multitude of industries, from automotive manufacturing to construction, making it essential for stakeholders to stay informed about the latest trends.

In this analysis, we will explore the top trends shaping the future of Hot Rolled Steel Coils. Enhanced manufacturing technologies, sustainability efforts, and changing consumer preferences are among the pivotal factors influencing the market. By understanding these trends, industry professionals can better position themselves to adapt to a dynamic environment and capitalize on emerging opportunities in the hot rolled steel sector.

As we delve into these trends, it becomes clear that the development and utilization of Hot Rolled Steel Coils will play an increasingly vital role in promoting efficiency and sustainability across various applications. Whether for cost-effectiveness, product quality, or environmental performance, this essential material will continue to be at the forefront of industrial advancement in the coming years.

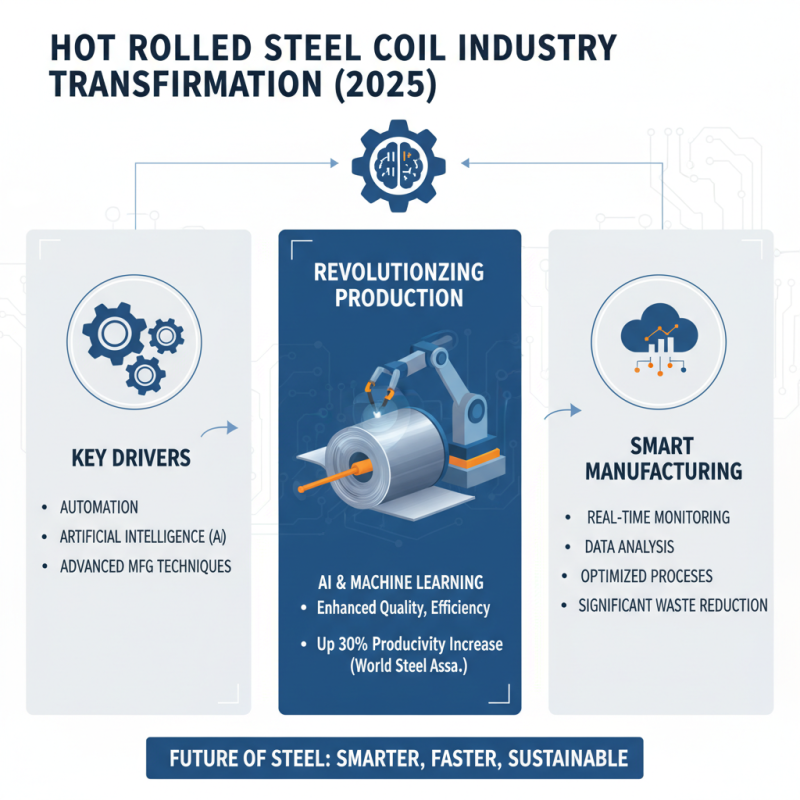

The hot rolled steel coil industry is undergoing rapid transformation driven by emerging technologies. As we approach 2025, advancements in automation, artificial intelligence (AI), and advanced manufacturing techniques are revolutionizing production processes. According to a report by the World Steel Association, utilizing AI and machine learning can enhance quality control and operational efficiency, potentially increasing productivity by up to 30% in the production of hot rolled steel coils. Furthermore, smart manufacturing technologies allow for real-time monitoring and data analysis, enabling manufacturers to optimize processes and reduce waste significantly.

Tips: To stay competitive, steel manufacturers should invest in developing skilled labor adept in data analytics and automation technologies. Adapting workforce upskilling programs will ensure that employees can leverage these advanced tools effectively.

The integration of renewable energy sources in steel production is another trend poised to make waves in 2025. A recent study from the International Energy Agency highlights that transitioning to low-carbon technologies, such as green hydrogen, could cut emissions from the hot rolled steel industry by 50%. This shift not only aligns with global sustainability targets but also positions companies favorably in a market increasingly focused on environmentally responsible practices.

Tips: Steel producers should explore partnerships with technology firms specializing in energy solutions to accelerate the transition toward greener production methods. These collaborations can foster innovation and help meet stringent regulatory requirements efficiently.

As we move toward 2025, the landscape of hot rolled steel coils is expected to shift dramatically due to changing market demands. Industries such as construction, automotive, and manufacturing are evolving, leading to increased requirements for high-strength and lightweight materials. This evolution is not just about meeting the current needs; it's about anticipating future demands that prioritize sustainability and efficiency. Consequently, companies in the steel industry must adapt their production strategies to align with these trends, focusing on innovations that enhance the quality and performance of hot rolled steel products.

The impact of these demand shifts on pricing is significant. With the surge in requirements for advanced materials, manufacturers may need to invest heavily in research and development, driving production costs higher. As a result, we may witness fluctuating prices in the hot rolled steel market. Moreover, geopolitical factors and raw material availability can further influence the pricing structure. Industry stakeholders must remain vigilant and responsive to these shifts, as they will not only shape their competitive edge but also determine the overall dynamics of the steel market in the years to come. Understanding these trends is crucial for making informed decisions in procurement and production planning.

Sustainability has emerged as a crucial focus in the hot rolled steel manufacturing processes, shaping the future of the industry. As environmental concerns become increasingly prominent, manufacturers are adopting innovative practices aimed at reducing the carbon footprint associated with steel production. This includes integrating renewable energy sources, such as solar and wind power, into the manufacturing process, which can significantly lower greenhouse gas emissions. Additionally, companies are exploring the use of electric arc furnaces that allow for the recycling of scrap steel, promoting a circular economy within the industry.

Moreover, advancements in technology play a vital role in enhancing sustainability in hot rolled steel manufacturing. The implementation of automation and smart manufacturing processes enables better resource management, reducing waste and energy consumption. Companies are now leveraging data analytics to optimize production processes, which not only increases efficiency but also minimizes environmental impact. By prioritizing sustainable practices, the hot rolled steel sector is not only responding to regulatory demands but is also positioning itself to meet the expectations of socially conscious consumers who are increasingly favoring environmentally friendly products.

This chart illustrates the key sustainability trends in hot rolled steel manufacturing for 2025. It compares target values against current levels for various metrics including recycled content, energy consumption, CO2 emissions, water usage, and waste reduction.

In 2025, the application of hot rolled steel coils is expected to witness significant innovations across various industries, primarily driven by advancements in manufacturing techniques and sustainability efforts. According to a recent report by the World Steel Association, the global consumption of hot rolled steel is projected to reach 1.6 billion tons by 2025, underlining its critical role in sectors such as construction, automotive, and energy. The versatility of hot rolled steel allows for greater flexibility in design and durability, making it an essential component in the development of modern infrastructure and machinery.

For instance, the construction sector is anticipated to increasingly utilize hot rolled steel coils due to their high strength-to-weight ratio, which enhances structural integrity while reducing material costs. A study by McKinsey & Company indicates that the use of advanced hot rolled steels can improve the energy efficiency of buildings by up to 30%, as they can accommodate larger spans and reduce the need for additional support beams. Furthermore, the automotive industry is also embracing innovations in hot rolled steel for manufacturing lighter, more fuel-efficient vehicles. As electric vehicles gain traction, the demand for high-strength, lightweight materials is expected to surge, providing growth opportunities for hot rolled steel applications.

Moreover, in response to environmental concerns, the steel industry is focusing on sustainable production methods. The use of electric arc furnaces (EAFs) to produce hot rolled steel coils is becoming more common, as EAFs typically emit 75% less CO2 compared to traditional blast furnaces. This shift not only aligns with global emissions reduction goals but also caters to the growing consumer preference for eco-friendly products. As innovations continue to evolve, hot rolled steel coils will play a pivotal role in meeting the challenges of modern manufacturing while adhering to sustainability principles.

As we approach 2025, the hot rolled steel industry is poised for transformative changes driven by regulatory shifts. Governments worldwide are increasingly focusing on sustainability and environmental protection, which directly impacts steel production processes. New regulations aimed at reducing carbon emissions will compel manufacturers to innovate and adopt cleaner technologies. This includes progressing from traditional methods to more eco-friendly alternatives, thereby reshaping the operational landscape of the industry.

In addition to environmental regulations, safety and quality standards are becoming increasingly stringent. Regulations governing workplace safety, employee rights, and product quality hold manufacturers accountable, promoting safer work environments and higher quality outputs. As businesses comply with these evolving standards, they may also need to invest in new training programs for their workforce, ensuring that all employees are equipped with the knowledge required to adhere to these regulations. Overall, the interplay of regulatory changes is set to redefine operational protocols, encouraging greater efficiency and sustainability in the hot rolled steel sector by 2025.