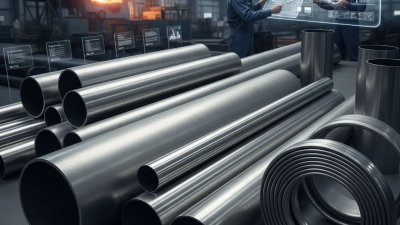

When it comes to selecting materials for construction projects, the choice of piping is critical to both performance and longevity. One material that has garnered significant attention in recent years is the carbon pipe. Known for its exceptional strength-to-weight ratio and versatility, carbon pipes present a compelling option for a variety of applications, from structural frameworks to fluid transportation systems. As construction demands evolve, understanding the advantages of carbon pipes becomes more essential for engineers and builders looking to optimize their projects.

Carbon pipes offer a unique combination of durability and flexibility, making them suitable for use in both small-scale constructions and large industrial applications. Their resistance to corrosion and high temperatures ensures that they can withstand challenging environments, thereby reducing the likelihood of maintenance issues over time. Additionally, the lightweight nature of carbon pipes facilitates easier handling and installation, ultimately leading to cost savings and improved efficiency on the job site.

In light of these benefits, choosing carbon pipes for your next construction project could be a strategic decision that enhances overall project outcomes. With their myriad advantages, carbon pipes are not just a trend but a sustainable solution for modern construction challenges, promising a high-performance alternative to traditional materials. As the industry continues to innovate, the role of carbon pipes as a preferred choice is poised to grow, offering unique solutions to meet the demands of various construction needs.

Carbon pipes have emerged as a preferred choice in the construction industry due to a plethora of benefits that enhance structural integrity and reduce overall project costs. One of the primary advantages of carbon pipes is their exceptional strength-to-weight ratio, which allows for lighter structures without compromising durability. This characteristic significantly eases transportation and installation, making them an efficient choice for project timelines while maintaining safety standards.

In addition to their mechanical properties, carbon pipes exhibit remarkable resistance to corrosion and wear, extending the lifespan of structures. This resilience reduces the need for frequent repairs and replacements, leading to long-term savings for construction projects. Furthermore, the versatility of carbon pipes enables their application across various sectors, from residential buildings to industrial facilities, demonstrating their adaptability to diverse construction needs. By choosing carbon pipes, builders can achieve not only superior performance but also sustainability in their construction practices.

| Dimension | Benefit | Application | Lifespan | Cost-Effectiveness |

|---|---|---|---|---|

| Standard Pipe Size | High tensile strength | Infrastructure projects | 50+ years | Long-term savings |

| Varied Diameters | Corrosion resistance | Water and sewage | 50+ years | Reduced maintenance |

| Lightweight | Ease of installation | Gas distribution | 50+ years | Lower labor costs |

| Variety of Finishes | Customizable | Industrial applications | 50+ years | Versatile use |

| High Pressure Capacity | Robust performance | High-pressure systems | 50+ years | Efficient operations |

When it comes to construction projects, the choice of materials can significantly influence the longevity and performance of the final structure. Carbon pipes have emerged as a popular choice due to their exceptional durability and strength compared to traditional materials such as steel or PVC. The inherent properties of carbon allow these pipes to withstand higher levels of stress and pressure, making them suitable for a variety of applications, from underground installations to high-pressure industrial environments. The resistance of carbon pipes to corrosion and wear further extends their lifespan, making them a cost-effective option in the long run.

In addition to their impressive strength, carbon pipes also offer advantages in terms of weight and flexibility. Unlike heavier materials, carbon pipes are lighter and more manageable, which simplifies transportation and installation processes. This lightweight nature does not compromise their structural integrity; rather, it enhances their usability in complex construction scenarios. Moreover, the flexibility of carbon pipes allows for easier maneuverability in various layouts and designs, accommodating the evolving needs of modern architecture. Hence, the combination of durability, strength, and practicality positions carbon pipes as an ideal choice for construction projects, paving the way for innovative and resilient building designs.

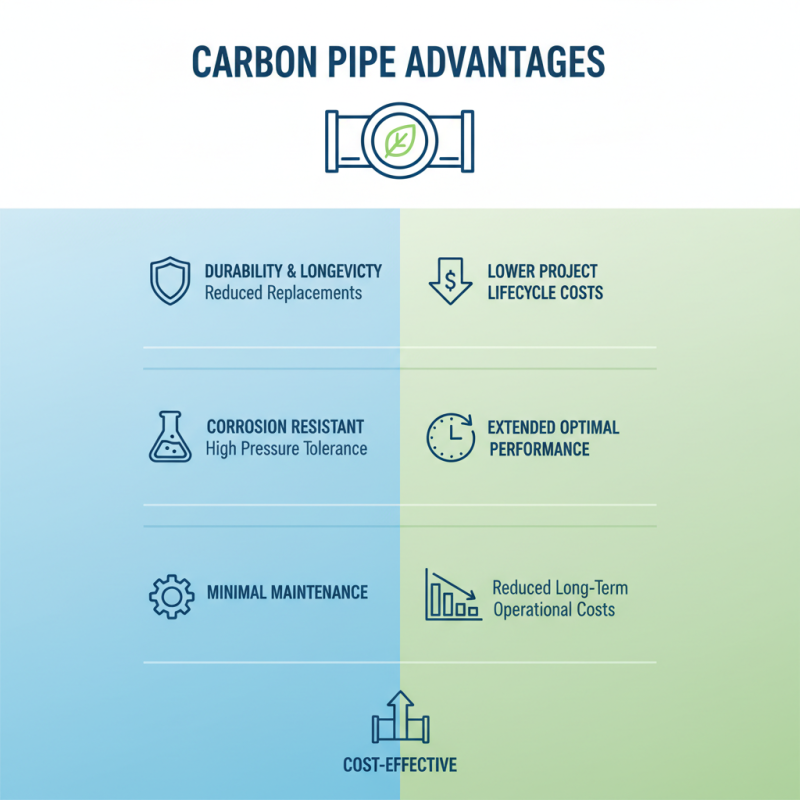

The cost-effectiveness of carbon pipes throughout the project lifecycle is one of the primary reasons for their increasing popularity in construction. Unlike traditional materials, carbon pipes offer superior durability and longevity, which significantly reduces the need for frequent replacements and maintenance. Their resistance to corrosion and ability to withstand high pressures mean that they can perform optimally over an extended period, ultimately cutting down on long-term operational costs.

Moreover, the initial investment in carbon pipes often pays off in the form of lower labor and installation costs. Lightweight and easy to handle, carbon pipes streamline the construction process, allowing for quicker installations and less reliance on heavy machinery. This efficiency not only accelerates project timelines but also leads to savings on labor expenses. When evaluated against the backdrop of total life-cycle costs, carbon pipes emerge as a financially savvy choice, contributing to both project budget adherence and overall profitability.

The use of carbon pipes in construction is increasingly being recognized for their environmental sustainability. Unlike traditional materials, carbon pipes are lightweight yet strong, leading to reduced energy consumption during transportation and installation. This energy efficiency is a crucial factor in minimizing the overall carbon footprint of construction projects. By opting for carbon pipes, builders can ensure that their projects not only meet structural requirements but also contribute to a more sustainable future.

In addition, carbon pipes are often made from recyclable materials, further enhancing their eco-friendly credentials. The ability to recycle these pipes at the end of their lifecycle means less waste in landfills, promoting a circular economy. Furthermore, the durability of carbon pipes ensures that they have a longer lifespan, reducing the need for frequent replacements and the environmental impact associated with producing new materials. As the construction industry seeks to adopt more sustainable practices, carbon pipes present a viable option that aligns with the global goal of reducing environmental impact while still achieving high-performance standards in building projects.

Carbon pipes have become a preferred choice in various construction applications due to their strength, durability, and cost-effectiveness. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), the global carbon pipe market is projected to grow at a CAGR of 4.5% from 2021 to 2026, driven by their increasing use in infrastructure projects. Carbon pipes excel in transporting fluids and gases, making them ideal for municipal water systems, sewage applications, and oil and gas transport. Their higher tensile strength compared to traditional materials ensures longevity and reduced maintenance costs, which is crucial for large-scale construction projects.

Another prominent application of carbon pipes is in structural components, particularly in high-rise buildings and bridges. According to the American Institute of Steel Construction (AISC), the integration of carbon pipes can enhance structural integrity while minimizing weight, allowing for more innovative architectural designs. Furthermore, the energy sector has significantly benefited from carbon pipes, where they are utilized in the construction of pipelines for power plants and refineries. Their resilience to extreme environmental conditions ensures that these vital infrastructures operate efficiently, further supporting the industry’s growth. As more construction projects prioritize sustainability and efficiency, the adoption of carbon pipes is set to increase significantly.